Borosonic Examination Service

Borosonic Examination Service Specification

- Interface

- Digital

- Weight

- Portable

- Temperature

- 0-50C Operating Temperature

- Driven Type

- Electric

- Material

- Stainless Steel

- Frequency

- 50 Hz

- Measuring Range

- 0.1 mm to 500 mm

- Voltage

- 220 V

- Display

- Digital

- Size

- Standard

- Power

- Wired

- Usage & Applications

- Industrial Flaw Detection, Material Testing, Weld Inspection

About Borosonic Examination Service

We provide a wide variety of Borosonic Examination Service to our valued customers. Borosonics are used with rotor material parameters, operating stress estimates, and fracture mechanics analysis to establish the rotor's current state and fitness for future service. The services provided are carried out with the use of cutting-edge technology and the assistance of professionals. Furthermore, this examination service is praised for its low pricing and flawless results. As a trusted company, we provide optimally professional service to ensure total customer satisfaction.

Product Details of Borosonic Examination Service

| Operating Systems Supported | Linux,Windows |

| Service Mode | Online |

| Training Duration | 3 months |

| Version Type | Internet |

| Type of Service Provider | Company |

| Frequency | Monthly |

Accurate and Reliable Flaw Detection Service

Borosonic Examination Service delivers superior accuracy in flaw detection and material analysis, facilitating critical inspections across a range of industrial environments. With high-precision digital measurement and strict calibration standards, this service ensures reliable results for safety and quality control. Instantaneous readings and real-time alarms further streamline operations, making it an essential tool for engineers and technicians.

Versatile Technology for Multiple Applications

This service employs interchangeable probes to accommodate a wide variety of industrial materials and inspection needs. Applicable in material testing, weld evaluation, and comprehensive flaw detection, its flexible design supports both manual and automated processes. The devices stainless steel construction and IP54 rating assure long-term durability even in challenging on-site conditions across India.

FAQs of Borosonic Examination Service:

Q: How does the Borosonic Examination Service achieve high-precision measurement?

A: The Borosonic Examination Service uses advanced probes and digital technology to deliver precise measurements with a range from 0.1 mm to 500 mm. Calibration can be performed both automatically and manually, ensuring sustained accuracy for every inspection.Q: What types of applications is this service best suited for?

A: This service is ideal for industrial flaw detection, weld inspection, and material testing. Its versatility and interchangeable probes make it suitable for various industries, including construction, manufacturing, and energy sectors across India.Q: When should I opt for manual scan mode versus automated scan?

A: Manual scan mode is best for small-scale or targeted inspections requiring operator control, while automated scan mode excels in large-scale or repetitive testing where increased efficiency and consistency are needed.Q: Where can the Borosonic Examination Service be used, considering environmental factors?

A: Equipped with an IP54 environmental rating and a working temperature range of 050C, the service can be used reliably on industrial sites with exposure to dust, moisture, or variable weather conditions in India.Q: What is the process for saving and retrieving test data?

A: Test data are automatically saved to the devices internal memory during each examination. Reports can be accessed easily through the digital interface, allowing users to review and export historical test results as required.Q: How do the audible and visual alarms benefit users during inspections?

A: The alarms provide immediate feedback when flaws or irregularities are detected, enabling quick response and minimizing the risk of overlooked issues during manual or automated scans.Q: What advantages does using interchangeable probes offer?

A: Interchangeable probes expand the range of detectable materials and applications, allowing the same equipment to be adapted for different inspection scenarios. This feature enhances efficiency and reduces overall operation costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Metal Testing Services Category

Welding Consultation Service

Price 5000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Expert advice and guidance on welding processes, project optimization, and problemsolving for fabrication, construction, maintenance, and manufacturing sectors

Material : ServiceBased (No physical material)

Display : Documented reports, presentations, online meetings

Size : Customizable as per client project needs

Risk Assessment Services

Price 50000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Risk identification, mitigation planning, safety compliance, industrial safety audits

Material : Not Applicable (servicebased)

Display : Detailed paper/digital report

Size : Customizable based on client facility

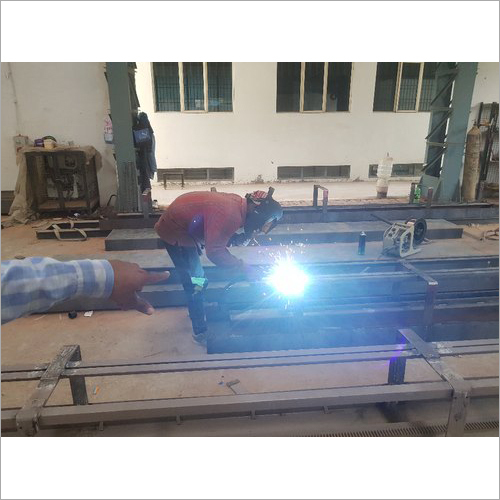

Welding Inspection Service

Price 5500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Quality inspection of welding processes

Material : Metal and Protective Gear

Display : Digital

Size : Customizable

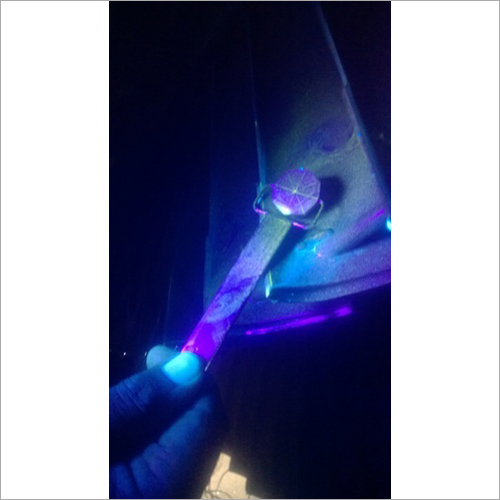

Fluorescent Testing Service

Usage & Applications : Material inspection

Material : Plastic

Display : Standard Display

Size : Small

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese