Visual Testing

Product Details:

Product Description

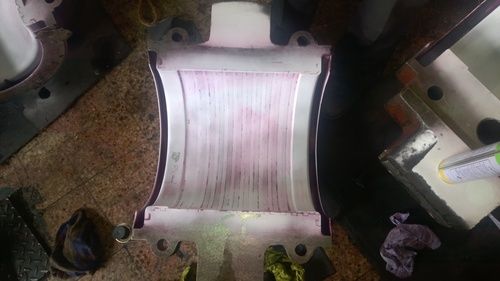

Visual inspection is the most widely used among all Non Destructive Tests. It is simple, easy to apply, quickly carried out, and usually low in cost. Even though a component is to be inspected using other NDT methods, a good visual inspection should be carried out first. A simple visual test can reveal gross surface defects thus leading to an immediate rejection of the component and consequently saving much time and money, which would otherwise be spent on more complicated means of testing. It is often necessary to examine for the presence of finer defects. For this purpose, visual methods have been developed to a very high degree of precision. With the advent of microprocessor and computers, visual examination can be carried out very reliably and with minimum cost. Image processing patterns recognition and automatic accept/reject choices are used when large numbers of components are to be assessed.

The basic procedure used in visual NDT involves illumination of the test specimen with light, usually in visible region. The specimen is then examined with eye or by light sensitive devices such as photocells. The equipment required for visual inspection is extremely simple, but adequate illumination is absolutely essential. The surface of the specimen should be adequately cleaned before being inspected.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Non Destructive Testing' category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese