Remote Field Eddy Current Testing of Heat Exchanger Tubes

Remote Field Eddy Current Testing of Heat Exchanger Tubes Specification

- Power

- 60W

- Temperature

- Operating range 0C to 50C

- Display

- Color LCD digital display, real-time flaw imaging

- Voltage

- Input 110-240V AC, 50/60Hz

- Driven Type

- Electric, automated probe drive

- Usage & Applications

- Detection of corrosion, wall loss, pitting in heat exchanger tubes

- Weight

- Portable probe unit approx. 1.5 kg

- Measuring Range

- Tube lengths up to 30 meters

- Frequency

- 10 Hz to 50 kHz (test selectable)

- Material

- Non-ferromagnetic alloys, stainless steel compatible

- Size

- Suitable for tube inner diameters 12mm to 50mm

- Interface

- USB, Ethernet, wireless data transmission

- Calibration

- Automatic and manual calibration modes

- Alarm System

- Audio-visual alarms for flaw detection

- Probe Type

- Remote field eddy current probe with interchangeable coil sets

- Detection Capabilities

- Detects through-wall defects, ID/OD pitting, baffle cuts

- Scan Speed

- Up to 1 meter per minute automatic scanning

- Resolution

- High sensitivity to wall thickness changes of 0.1 mm

- Data Storage

- Internal memory and external USB support

- Compliance

- ASTM E2096 standard, CE certified

- Software

- Comprehensive analysis software with reporting generation

- Environmental Protection

- IP54 rated for dust and water splashes

- Accessories Included

- Probe adapters, calibration tubes, carrying case

- Cable Length

- Standard 15m probe cable, extendable up to 30m

Remote Field Eddy Current Testing of Heat Exchanger Tubes Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- North India

- Certifications

- ASNT, ISO, NABL, etc.

About Remote Field Eddy Current Testing of Heat Exchanger Tubes

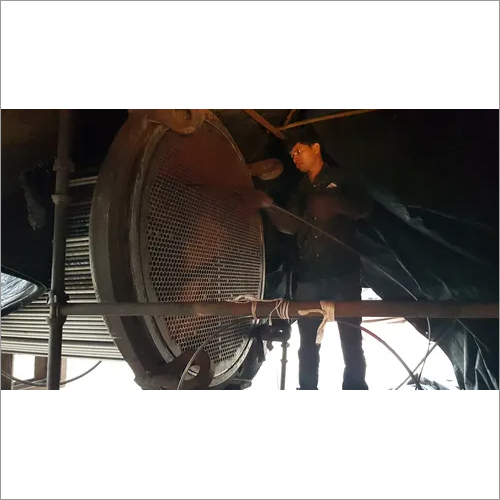

REMOTE-FIELDEDDY CURRENT (RFEC) TESTING is a non destructive examination technique suitablefor the examination of conducting tubular goods using a probe from the inner surface. Because of the RFEC effect, the technique provides what is, in effect,a through-wall examination using only the interior probe. Although thetechnique is applicable to any conducting tubular material, it has been primarily applied to ferro magnetics because conventional eddy current testing techniquesare not suitable for detecting opposite-wall defects in such material unlessthe material can be magnetically saturated. In this case, corrosion/erosion wall thinning and pitting as well as cracking are the flaws of interest. One advantage of RFEC inspection for either ferromagnetic or non ferro magneticmaterial inspection is that the probe can be made more flexible than saturation eddy current or magnetic probes, thus facilitating the examination of tubes with bends or diameter changes. Another advantage of RFEC inspection is that itis approximately equal (within a factor of 2) in sensitivity to axially and circumferentially oriented flaws in ferromagnetic material. The major disadvantage of RFEC inspection is that, when applied to non ferromagnetic material, it isnot generally as sensitive or accurate as traditional eddy current testing techniques.

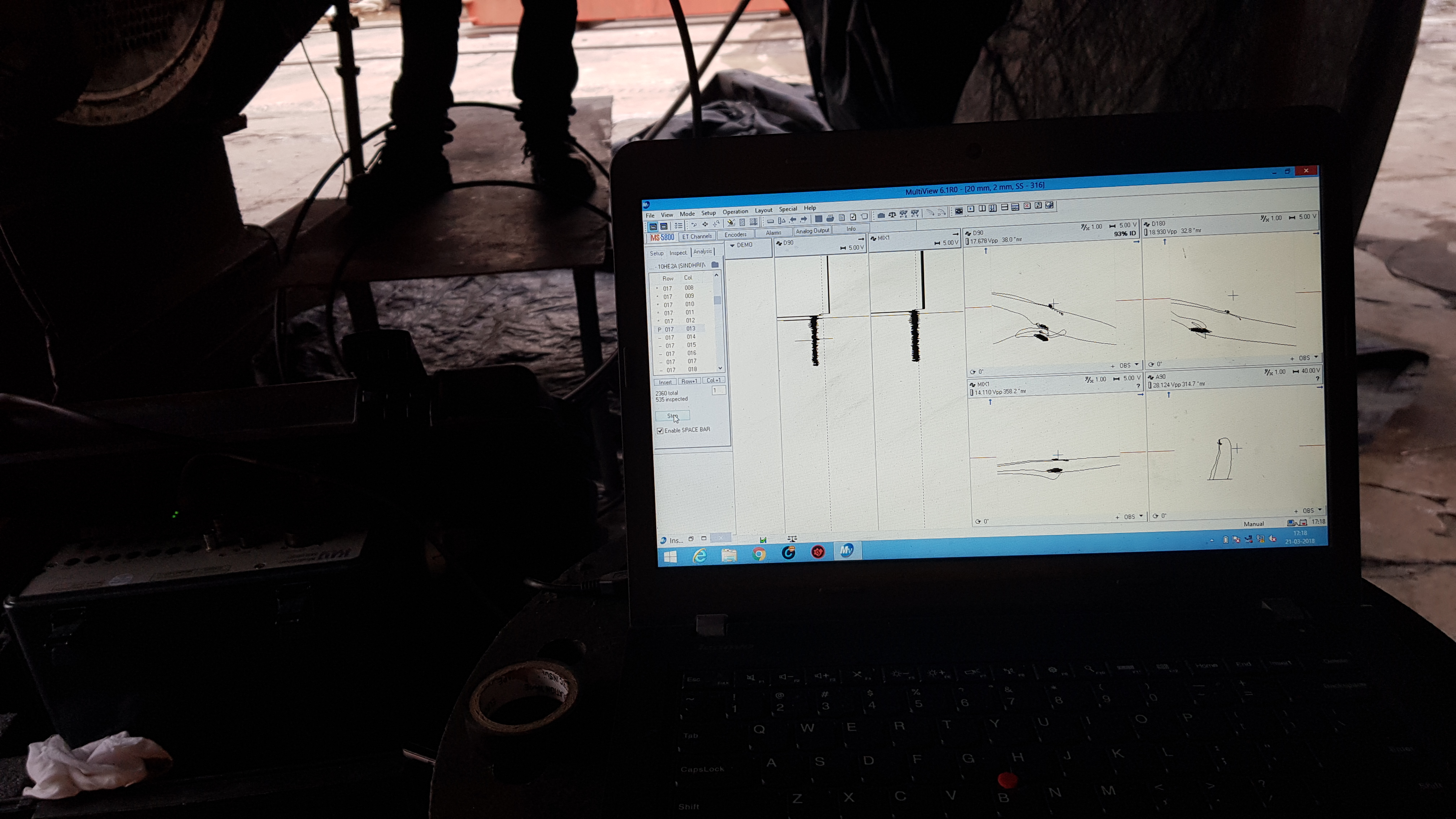

AtITE, we use Olympus MS 5800 for Remote Field Electromagnetic Testing in various components like Heat Exchangers, Reactors, Condensers, etc. All those tubeswhich are ferromagnetic in nature like made from the alloys of Steel, Nickel,etc. are tested. We have a formidable customer base for RFET like IOCL, NFL,JLSL, etc. to name a few.

Areas Served :- Delhi, Uttar Pradesh, Haryana, Punjab, Maharashtra, Bihar, Rajasthan, Himachal Pradesh, Uttarakhand, Madhya Pradesh, Jammu & Kashmir, Gujarat, Sikkim, Arunachal Pradesh, Greater Noida, Ghaziabad, Noida, Nepal, Entire North India and South India, United Arab Emirates, Dubai, Qatar, Saudi Arabia, Africa, Egypt, Bahrain, Oman, etc.

High-Resolution Flaw Detection

The remote field probe delivers outstanding sensitivity for distinguishing wall thickness changes as minute as 0.1 mm. Capable of reliably detecting through-wall flaws, pitting on both inner and outer diameters, and baffle cuts, this instrument ensures comprehensive integrity assessment for heat exchanger tubes. Each scan offers the clarity required for critical inspections, supporting robust maintenance decisions.

Compatible and User-Friendly Design

Designed for heat exchanger tubes with internal diameters between 12 mm and 50 mm, the RFET systems modular probe with interchangeable coil sets adapts quickly to various tube sizes. The instrument is portable, weighing just 1.5 kg, with a standard 15 m cable extendable to 30 m, enabling easy maneuverability in field environments. Accessories like adapters and calibration tubes enhance its usability.

Intelligent Data Analysis and Reporting

Advanced software supports real-time flaw imaging, automated and manual calibration, and detailed reporting. Store scan data internally or export via USB, Ethernet, or wireless connections. The system simplifies analysis, increases documentation efficiency, and provides alarms for immediate flaw notification, empowering teams to respond swiftly to inspection findings.

FAQs of Remote Field Eddy Current Testing of Heat Exchanger Tubes:

Q: How does the RFET probe detect flaws in heat exchanger tubes?

A: The remote field eddy current probe uses electromagnetic principles to sense variations in wall thickness and material properties. High-sensitivity coils detect changes as small as 0.1 mm, allowing identification of corrosion, wall loss, ID/OD pitting, and through-wall defects within tubes.Q: What types of tubes and materials are compatible with this system?

A: This system is compatible with non-ferromagnetic alloy and stainless steel heat exchanger tubes, accommodating inner diameters from 12 mm to 50 mm and lengths up to 30 meters. Its interchangeable coil sets and adjustable cable length ensure adaptability for various inspection needs.Q: When and where should remote field eddy current testing be applied?

A: RFET is ideal during routine maintenance, commissioning, and outage inspections at power plants, refineries, petrochemical plants, or any facility utilizing heat exchanger tubes made of compatible materials. Use it whenever early detection of flaws or corrosion is crucial for operational safety and efficiency.Q: What is the process for conducting an RFET inspection?

A: First, select and attach the suitable coil set for the tube size. Calibrate the system (either automatically or manually), insert the probe into the tube, and initiate automated scanning at up to 1 meter per minute. The system captures and displays real-time flaw imagery, triggers audio-visual alarms upon flaw detection, and stores the inspection data for analysis and reporting.Q: How is the data managed and reported after an inspection?

A: Inspection data is stored internally and can be exported via USB, Ethernet, or wirelessly. The comprehensive analysis software enables real-time flaw imaging, automatic report generation, and easy documentation, ensuring traceability and quick dissemination of inspection results.Q: What are the main benefits of using this RFET solution?

A: Key benefits include high-resolution flaw detection, rapid and efficient scanning, comprehensive data management, compliance with ASTM E2096 and CE standards, portability, and suitability for harsh environments (IP54). This enables proactive maintenance and reduced downtime.

- Main Domestic Market

- North India

- Main Export Market(s)

- Middle East, Africa, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Eddy Current Testing of Heat Exchanger Tubes (ECT)

Measuring Range : Tube length up to 20 meters

Frequency : 10 Hz to 10 MHz adjustable

Material : Stainless Steel, Copper, Brass, Titanium (as per tube material)

Size : Any tube OD, typically 6mm to 50mm

Interface : USB, Ethernet, RS232

Power : Max 100 W

Oxide Scale Measurement of for boiler tubes

Measuring Range : 05 mm (oxide scale thickness)

Frequency : 50/60 Hz (for AC powered models)

Material : Highgrade stainless steel and industry alloy

Size : Customizable (commonly 860 mm diameter tubes)

Interface : Digital with USB or serial output (RS232/RS485 options)

Power : Battery operated or mains powered

Online Condenser Helium Leak Testing

Measuring Range : 1 x 10 mbarl/sec to 1 x 10 mbarl/sec

Frequency : 50/60 Hz

Material : Stainless Steel

Size : Custom / As per requirement

Interface : Digital Interface with alarm system

Power : 1.52 kW

Time of Flight Diffraction

Measuring Range : 1 mm to 500 mm (depending on probe and material)

Frequency : 50/60 Hz

Material : Industrial Grade Components

Size : Portable, Handheld Unit

Interface : USB, Ethernet

Power : Rechargeable Lithiumion Battery or Mains

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese