Liquid Penetrant Testing

Liquid Penetrant Testing Trade Information

- Main Domestic Market

- North India

About Liquid Penetrant Testing

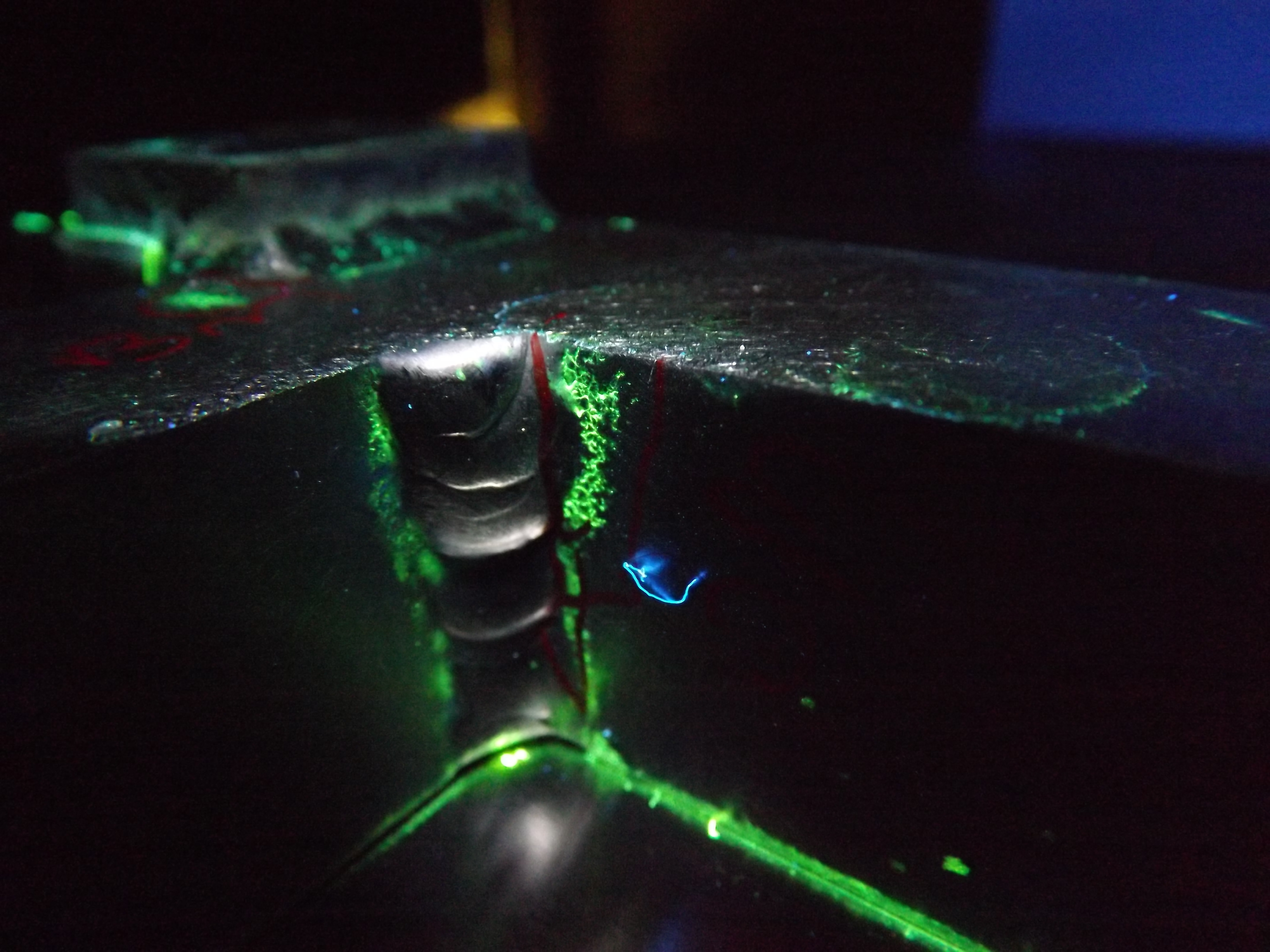

Liquid penetrant testing, also known as Dye Penetrant Inspection, is a widely used non destructive testing method that allows engineers to identify surface breaking defects in materials. It is a simple and cost effective way to detect small cracks, porosity, laps, and other discontinuities that are not visible to the naked eye. Liquid penetrant testing, also known as Dye Penetrant Inspection, is a widely used non destructive testing method that allows engineers to identify surface breaking defects in materials. It is a simple and cost effective way to detect small cracks, porosity, laps, and other discontinuities that are not visible to the naked eye.

The basic principle of liquid penetrant testing is to use a highly visible dye that is applied to the surface of the material being tested. The dye penetrates into any surface discontinuities by capillary action and then is removed from the surface. A developer is then applied to the surface, which draws the dye back out of the discontinuity and highlights its location on the surface. This method can be used on a variety of materials, including metals, plastics, ceramics, and composites.

The process of liquid penetrant testing involves several steps. First, the surface being tested must be cleaned thoroughly to remove any contaminants that could interfere with the testing process. Next, the penetrant is applied to the surface and allowed to soak in for a specified amount of time. Excess penetrant is then removed, and the developer is applied to the surface, which draws the penetrant back out of any surface discontinuities. Liquid penetrant testing has several advantages over other testing methods. It is easy to perform, requires minimal training, and can detect surface discontinuities that might be missed by visual inspection. However, it does have limitations. It cannot detect subsurface defects, and it can only detect defects that are open to the surface. Additionally, the penetrant materials used in this method can be messy and may require special handling and disposal.

In summary, liquid penetrant testing is a valuable tool for engineers and can be used to detect surface breaking defects in a variety of materials. It is a simple, cost effective, and reliable method that can be used in a variety of industries, including aerospace, automotive, and construction.

Product details

|

Place of Service |

Factories |

|

Time Duration |

2 to 3 Hours |

|

Technology |

Pentration |

|

Metal Type |

Ferrous Metal |

|

Mode |

Offline |

|

Service Type |

Testing |

|

Place of Service |

Factories |

|

Time Duration |

2 to 3 Hours |

|

Technology |

Pentration |

|

Metal Type |

Ferrous Metal |

|

Mode |

Offline |

|

Service Type |

Testing |

- Main Domestic Market

- North India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Destructive Testing Category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese