Hardness Metals Testing Services

Hardness Metals Testing Services Specification

- Frequency

- 50 Hz

- Measuring Range

- Up to 800 HV/HB/HRB/HRC depending on the test method

- Voltage

- 220 V AC

- Temperature

- Ambient to 45C

- Driven Type

- Electric

- Usage & Applications

- Determining hardness of metal components, quality control, research & development, industrial inspection

- Size

- Standard / Customized

- Display

- Digital/Analog

- Weight

- As per sample/component

- Material

- Metals

- Power

- 1 kW (typical)

- Interface

- Digital/Analog Output (as per testing machine)

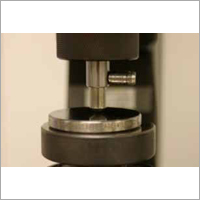

About Hardness Metals Testing Services

The Hardness Metals Testing Services of material means the capacity to permanently deform into plastic. Hardness testing methods such as ultrasonic, electromagnetic, and rebound are used in a variety of applications to determine the hardness of various materials. Hardness testing of various materials is critical in a variety of industries, including automotive, structural, failure analysis, quality control, aerospace, and others. Case depth analysis and the ability to verify the heat treatment of a part in heat-treating activities. Hardness Metal Testing Service determines whether or not a substance has the qualities required for its intended purpose.

Product Details of Hardness Metals Testing Services

|

Certification Scheme |

Employer Based Certification |

|

Product Type |

Concrete Mix Design |

|

Application |

Production and Manufacturing |

|

Sampling Procedure |

On-Site Testing |

|

Client Profile |

Building Owner |

|

Sampling Area |

In-House |

|

Value Data Report on |

Material Properties |

|

Testing Type |

Bearing Capacity Testing |

|

Material Type |

Cement |

|

Testing Parameter |

Sulphur Content |

Precise Metal Hardness Assessment

We use Brinell, Rockwell, and Vickers hardness testing techniques to accurately determine the hardness of your metal samples. Our expertise covers both ferrous and non-ferrous materials, providing essential data for quality control and industrial applications.

Flexible Service Delivery Across India

Choose either on-site or laboratory testing based on your operational convenience. Our equipped teams can test samples at your facility or in our specialized labs, ensuring minimal disruptions and comprehensive service coverage nationwide.

Comprehensive and Reliable Test Reports

Receive in-depth analysis including hardness values, impression dimensions, and statistical evaluations. Reports can feature photographs and graphical representations for easy interpretation. Our results are based on internationally traceable calibrations for maximum reliability.

FAQ's of Hardness Metals Testing Services:

Q: How do you determine the appropriate hardness testing method for a metal sample?

A: The selection of Brinell, Rockwell, or Vickers hardness test is based on the type, size, and hardness range of the metal. Our metallurgists assess the sample's characteristics and application requirements, then recommend the most suitable method for accurate results.Q: What types of metals and sample sizes can you test?

A: We test both ferrous and non-ferrous metals, accommodating standard and customized sample sizes. Whether your samples are small components or larger metal pieces, our equipment and skilled operators can handle a wide range of shapes and weights.Q: When can I expect the hardness test results?

A: Typically, test reports are delivered within 2 to 4 working days after sample receipt or site visit, subject to current workload and service location. Our efficient processes ensure prompt turnaround without compromising accuracy.Q: Where are your hardness testing services available?

A: Our services are available across India, providing both on-site testing at your facility and in-lab testing at our advanced laboratories. This flexibility lets you choose the most convenient and efficient option for your needs.Q: What does your hardness test report include?

A: Each report features comprehensive hardness values, impression dimensions, and statistical analysis. Photographs and graphical data are included if required, ensuring clarity for quality checks, research, or industrial assessments.Q: How is calibration maintained for your equipment?

A: All our testing machines are calibrated with standards traceable to national and international references, ensuring the credibility and accuracy of every hardness assessment conducted.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Metal Testing Services Category

RFET ( Remote Field Electromagnetic Testing)

Price 35000 INR / Piece

Minimum Order Quantity : 1 ,

Usage & Applications : Heat exchanger tube inspections pipeline testing

Display : LCD

Weight : Lightweight approx. 23 kg

Material : Stainless steel and composite materials

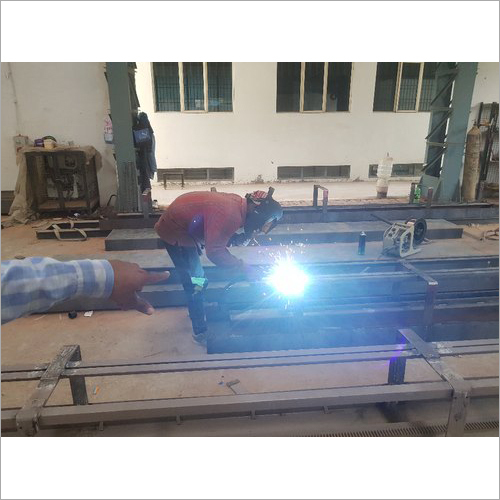

Welding Consultation Service

Price 5000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage & Applications : Expert advice and guidance on welding processes, project optimization, and problemsolving for fabrication, construction, maintenance, and manufacturing sectors

Display : Documented reports, presentations, online meetings

Weight : Not applicable for consultation services

Material : ServiceBased (No physical material)

Borosonic Examination Service

Usage & Applications : Industrial Flaw Detection, Material Testing, Weld Inspection

Display : Digital

Weight : Portable

Material : Stainless Steel

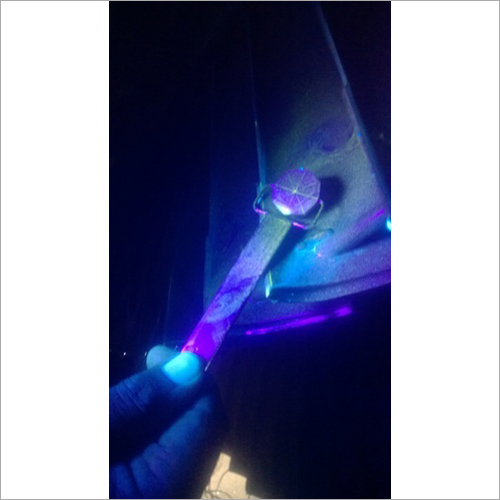

Fluorescent Testing Service

Usage & Applications : Material inspection

Display : Standard Display

Weight : Lightweight

Material : Plastic

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese