Eddy Current Testing of Heat Exchanger Tubes (ECT)

Eddy Current Testing of Heat Exchanger Tubes (ECT) Specification

- Size

- Any tube OD, typically 6mm to 50mm

- Weight

- Portable setup, approximately 5-8 kg

- Usage & Applications

- Detection of defects, cracks, corrosion, and wall thinning in heat exchanger and condenser tubes in various industries such as power plants, refineries, petrochemical, and HVAC plants

- Frequency

- 10 Hz to 10 MHz adjustable

- Display

- LCD/LED digital display

- Temperature

- Operating range: 0C to 50C

- Power

- Max 100 W

- Interface

- USB, Ethernet, RS232

- Measuring Range

- Tube length up to 20 meters

- Driven Type

- Electrically operated

- Voltage

- 110V/220V AC, 50-60 Hz

- Material

- Stainless Steel, Copper, Brass, Titanium (as per tube material)

Eddy Current Testing of Heat Exchanger Tubes (ECT) Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- All India

- Certifications

- ASNT, NABL, ISO, etc.

About Eddy Current Testing of Heat Exchanger Tubes (ECT)

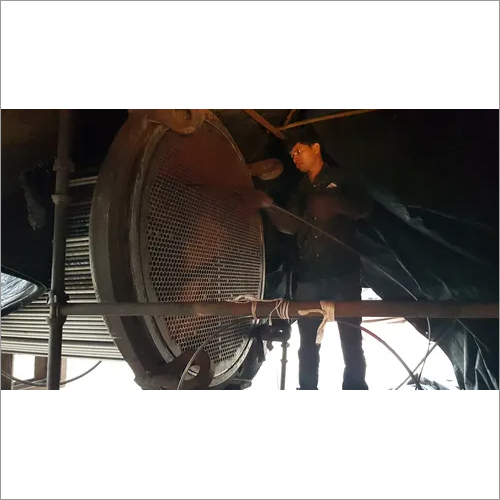

ITE has been performing Eddy Current Testing of tubes for more than a decade.

EDDY CURRENT INSPECTION is based on the principles of electromagnetic induction and is used to identify or differentiate among a wide variety of physical, structural, and metallurgical conditions in electrically conductive ferromagnetic and non ferro magneticmetals and metal parts.

Because eddy currents are created using an electromagnetic induction technique, the inspection method does not require direc telectrical contact with the part being inspected. The eddy current method is adaptable to high-speed inspection and because it is nondestructive, can be used to inspect an entire production output if desired. The method is based onindirect measurement,and the correlation between the instrument readings and the structural characteristics and serviceability of the parts being inspected must be carefully and repeatedly established

AtITE, we use Olympus MS 5800 for Eddy Current Testing of Tubes in various components like Heat Exchangers, Reactors, Condensers, etc. All those tubes which are non ferromagnetic in nature like made from the alloys of Aluminium,Copper, Austenitic Stainless Steel, Titanium, etc. are tested. We have a formidable customer base for ECT like IOCL, NFL, KSFL, NPL, IFFCO, etc. to namea few.

Locations servced are Delhi, Uttar Pradesh, Maharashtra, Punjab, Rajasthan, Bihar, Gujarat, Haryana, Uttarakhand, Jammu & Kashmir, Himachal Pradesh, Madhya Pradesh, Sikkim, Arunachal Pradesh, Nepal and rest of India.

Advanced Flaw Detection for Critical Assets

ECT provides high-sensitivity inspection for heat exchanger and condenser tubes, swiftly detecting corrosion, cracks, and wall thinning. Equipped with interchangeable probe coils and advanced flaw characterization software, the system adapts to varied tube diameters, ensuring comprehensive coverage. Automated alarms and clear displays support prompt operator response.

Data Integrity and Effortless Reporting

All measurements are securely stored on internal flash memory or exportable via USB. Comprehensive automated reports can be generated instantly in PDF or CSV formats, facilitating compliance and data analysis. User-friendly interfaces and compatibility with multiple communication protocols simplify setup and result management.

Rugged, Portable, and Adaptable Design

Engineered for on-site testing, the portable ECT unit weighs just 58 kg, includes an IP54 water and dust-resistant enclosure, and operates between 0C and 50C. Factory calibration with on-site verification ensures ongoing testing accuracy, making it suitable for demanding industrial environments experienced in India.

FAQs of Eddy Current Testing of Heat Exchanger Tubes (ECT):

Q: How does Eddy Current Testing (ECT) identify defects in heat exchanger tubes?

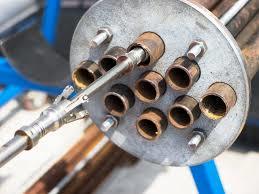

A: ECT detects electromagnetic response differences caused by flaws such as cracks, corrosion, and wall thinning. Customized coil probes (absolute or differential) for each tube size, combined with high-sensitivity electronics, enable reliable identification of defects as small as 0.5 mm along the entire tube length.Q: What types of probe coils are compatible with various tube materials and sizes?

A: The system supports absolute and differential coil probes, tailored to work with a range of ferrous or non-ferrous tubes. Users can inspect diameters typically between 6 mm and 50 mm, with probes suited for materials like stainless steel, copper, brass, and titanium.Q: When should heat exchanger tubes be tested using ECT?

A: ECT is ideal during routine maintenance, shutdowns, or as part of scheduled integrity assessments. Early detection of defects enables timely repairs and helps prevent unexpected failures in critical environments, such as power plants and refineries.Q: Where can this ECT system be used safely and efficiently?

A: With its portable 58 kg build and IP54-rated enclosure, the ECT system is suitable for on-site environments that are exposed to water or dust, including power generation facilities, petrochemical plants, and HVAC installations across India.Q: What is the procedure for using the ECT system on-site?

A: Operators connect the coil probe to the unit, insert it along the tube (up to 20 meters), and initiate the scan via the user interface. Visual and audio alarms indicate flaw locations, while internal and USB flash storage automatically logs results for later export and reporting.Q: How does automated reporting and data storage benefit users?

A: Automated report generation creates standardized documents (PDF or CSV), enabling fast compliance and easy sharing of inspection results. Secure internal memory and USB support provide flexible, redundant storage options.

- Main Domestic Market

- All India

- Main Export Market(s)

- Middle East, Africa, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Time of Flight Diffraction

Power : Rechargeable Lithiumion Battery or Mains

Size : Portable, Handheld Unit

Display : HighResolution Colour LCD

Temperature : 10C to 50C (Operating)

Measuring Range : 1 mm to 500 mm (depending on probe and material)

Driven Type : Electric

Remote Field Eddy Current Testing of Heat Exchanger Tubes

Power : 60W

Size : Suitable for tube inner diameters 12mm to 50mm

Display : Color LCD digital display, realtime flaw imaging

Temperature : Operating range 0C to 50C

Measuring Range : Tube lengths up to 30 meters

Driven Type : Electric, automated probe drive

Internal Rotatory Inspection System

Power : 100 W

Size : Customizable as per requirement

Display : Highresolution LCD

Temperature : Operating range 0C to 60C

Measuring Range : 40 mm to 400 mm (internal diameters)

Driven Type : Motorized

Borescopic Inspection Services

Power : Rechargeable battery or mains powered supply

Size : Customizable Probe Lengths (commonly 1m to 10m)

Display : Highresolution LCD, LED or TFT digital display

Temperature : Operating range from 10C to 60C (probe dependent)

Measuring Range : Visual inspection only; Not a dimensional measuring tool

Driven Type : Manual articulated or motorized control depending on probe type

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese