Internal Rotatory Inspection System

Internal Rotatory Inspection System Specification

- Usage & Applications

- Inspection of internal surfaces of pipes and tubes

- Driven Type

- Motorized

- Weight

- Approx. 10-15 kg

- Temperature

- Operating range 0C to 60C

- Interface

- Digital & Analog options

- Measuring Range

- 40 mm to 400 mm (internal diameters)

- Size

- Customizable as per requirement

- Voltage

- 230 V AC

- Material

- Stainless Steel

- Power

- 100 W

- Frequency

- 50 Hz

- Display

- High-resolution LCD

- Camera Type

- High-definition rotatory camera

- Safety Features

- Overload and overheat protection

- Mounting

- Tripod or portable handheld

- Accessories Included

- Carrying case, control unit, cables

- Cable Length

- 15 meters (extendable)

- Control Method

- Remote control with real-time video feed

- Image Capture

- Still image and video recording capability

- Resolution

- Up to 1920x1080 pixels (Full HD)

- Rotation Angle

- 360-degree continuous rotation

- Operating Humidity

- Up to 95% non-condensing

- Lighting

- Integrated LED ring illumination

Internal Rotatory Inspection System Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- North India

- Certifications

- ASNT, ISO, NABL

About Internal Rotatory Inspection System

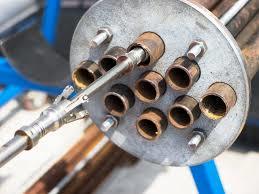

IRIS is used ofinspecting the internal of tupes/pipes which otherwise are not accessible fortesting with any other methods. Unlike Eddy Current Testing or RFET, it cantell us the exact thickness of the are under inspection and the flaw itself.

With Internal Rotary Inspection System, we can detectcorrosion, pitting and wallloss and is commonly used for tube inspection in boilers, heat exchangers, aircoolers and feed water heaters. It is particularly versatile as it is suitablefor both ferrous and non-ferrous materials, and IRIS can be used on a widerange of tube diameters and wall thicknesses.

An IRIS probe is inserted into a tube flooded with water. The probe is fittedwith a turbine and a transducer that generates an ultrasonic pulse along a pathparallel to the axis of the tube. A rotating mirror directs the ultrasonicpulse into the tube wall. The mirror is driven by a small turbine that isrotated by the pressure of water pumped into the tube.

Ultrasonic Pulses are reflected from the outer dia of the tube and then returnto the IRIS probe/sensor and gives us the indication of flaw, if any.

As the IRIS probe is pulled, the spinning motion of the mirror results in ahelical scan path ensuring full coverage of the tube.

Benefits of using IRIS include:

- Suitability for both ferrous and non-ferrous materials

- Detection of corrosion, pitting and thickness loss

- Accurate wall thickness measurements

- Sensitivity to both internal and external defects

- Defect position can be located in relation to tube length

- Complete coverage of the tube

- Results data storage

- Flexibility as a back-up to remote field, magnetic flux leakage and eddy current inspections.

Areas Served :- Delhi, Uttar Pradesh, Haryana, Punjab, Maharashtra, Bihar, Rajasthan, Himachal Pradesh, Uttarakhand, Madhya Pradesh, Jammu & Kashmir, Gujarat, Sikkim, Greater Noida, Ghaziabad, Noida, Nepal, Entire North India and South India, United Arab Emirates, Dubai, Qatar, Saudi Arabia, Africa, Egypt, Bahrain, Oman, etc.

Precision in Pipe and Tube Inspections

This inspection system is specifically crafted for internal surfaces of pipes and tubes ranging from 40 mm to 400 mm in diameter. Its advanced rotatory mechanism paired with HD video capture ensures comprehensive evaluation of challenging, confined spaces, aiding industries in preventing undetected faults and minimizing downtime.

Remote-Controlled Operation and Real-Time Monitoring

Inspection tasks become more efficient with the remote-controlled rotation and real-time high-resolution video feed displayed on an LCD screen. Operators can capture images and record videos to document findings for thorough analysis and easy reporting, streamlining quality assurance and maintenance procedures.

Rugged Design for Reliability

Manufactured from stainless steel and built to withstand harsh environments, the system offers robust safety features, including overheat and overload protection. Its adaptable design (tripod or handheld use) and comprehensive kitincluding a carrying case and control unitmake it ideal for on-site service across varying industrial applications in India.

FAQs of Internal Rotatory Inspection System:

Q: How is the Internal Rotatory Inspection System operated during an inspection?

A: The system features a remote control, allowing users to maneuver the high-definition rotatory camera with 360-degree continuous rotation. The integrated LED ring ensures excellent illumination while a high-resolution LCD displays a real-time video feed for precise internal inspection.Q: What types of pipes or tubes can this inspection system assess?

A: This inspection system is designed for internal examination of pipes and tubes ranging from 40 mm to 400 mm in internal diameter, making it ideal for a broad spectrum of industrial and infrastructure applications.Q: When should I use the Internal Rotatory Inspection System?

A: The system should be used whenever detailed internal visual checks are required, such as during preventive maintenance, troubleshooting suspected issues, or after repairs to verify structural integrity and cleanliness of pipes or tubes.Q: Where can the inspection system be deployed in India?

A: The system is portable and suitable for use across various locations in India, wherever access to pipe or tube interiors is needed, such as waterworks, power plants, refineries, factories, and construction sites.Q: What is the process for capturing and documenting inspection results?

A: Operators use the remote control to maneuver the camera and utilize the systems still image and video recording functions. Data is displayed instantly on the LCD and can be saved for further analysis, reporting, or recordkeeping.Q: What are the main benefits of using this inspection system?

A: Key benefits include enhanced inspection accuracy due to Full HD resolution, reliable performance with overload and overheat protection, versatility through digital and analog outputs, and ease of transport with a dedicated carrying case.Q: Is the cable length customizable to suit different inspection environments?

A: The standard system comes with a 15-meter cable, which can be extended as needed to accommodate specific pipe lengths or challenging environments, providing flexibility for diverse inspection scenarios.

- Main Domestic Market

- North India

- Main Export Market(s)

- Middle East, Africa, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Helium Leak Testing

Measuring Range : 10 to 1 mbar l/s

Voltage : 110240 V AC

Size : Customizable or standard depending on application

Temperature : Operating range: 0C to 50C

Interface : Digital and analog output interfaces, RS232/RS485, USB

Display : Digital LCD/LED

Oxide Scale Measurement of for boiler tubes

Measuring Range : 05 mm (oxide scale thickness)

Voltage : AC 220V 10% / 50Hz or internal rechargeable Liion battery

Size : Customizable (commonly 860 mm diameter tubes)

Temperature : Measuring capacity up to 600C (device operating range 050C)

Interface : Digital with USB or serial output (RS232/RS485 options)

Display : Highcontrast backlit LCD digital display

Borescopic Inspection Services

Measuring Range : Visual inspection only; Not a dimensional measuring tool

Voltage : AC 110240V (adapter for equipment), or DC 12V (battery)

Size : Customizable Probe Lengths (commonly 1m to 10m)

Temperature : Operating range from 10C to 60C (probe dependent)

Interface : Compatible with digital displays, USB, SD card, and video output interfaces.

Display : Highresolution LCD, LED or TFT digital display

Online Condenser Helium Leak Testing

Measuring Range : 1 x 10 mbarl/sec to 1 x 10 mbarl/sec

Voltage : 220240V AC

Size : Custom / As per requirement

Temperature : Operating range: 10C to 50C

Interface : Digital Interface with alarm system

Display : Digital LCD/LED Display

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese