Visual Testing

Visual Testing Specification

- Temperature

- 0 to 50C

- Interface

- Digital display

- Measuring Range

- Up to 100 mm (depth)

- Voltage

- 220V AC

- Driven Type

- Electric

- Usage & Applications

- Weld inspection, surface flaw detection, quality control

- Power

- 20W

- Frequency

- 50 Hz

- Size

- Portable / Handheld

- Material

- mild steel

- Weight

- 1.5 kg

- Display

- LCD/LED

- Operation Time

- Up to 12 hours continuous use (Battery mode)

- Calibration

- Factory Pre-calibrated with User Adjustment Option

- Resolution

- High Clarity Optics for Microscopic Details

- Magnification

- Up to 20x Optical Zoom

- Protection Class

- IP54 Dust and Water Resistant

- Compliance

- Meets International NDT Standards (ISO, ASTM)

- Storage

- Internal Memory for Inspection Records

- Lighting

- Integrated LED Illumination

Visual Testing Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Domestic Market

- North India

About Visual Testing

Visual inspection is the most widely used among all Non Destructive Tests. It is simple, easy to apply, quickly carried out, and usually low in cost. Even though a component is to be inspected using other NDT methods, a good visual inspection should be carried out first. A simple visual test can reveal gross surface defects thus leading to an immediate rejection of the component and consequently saving much time and money, which would otherwise be spent on more complicated means of testing. It is often necessary to examine for the presence of finer defects. For this purpose, visual methods have been developed to a very high degree of precision. With the advent of microprocessor and computers, visual examination can be carried out very reliably and with minimum cost. Image processing patterns recognition and automatic accept/reject choices are used when large numbers of components are to be assessed.

The basic procedure used in visual NDT involves illumination of the test specimen with light, usually in visible region. The specimen is then examined with eye or by light sensitive devices such as photocells. The equipment required for visual inspection is extremely simple, but adequate illumination is absolutely essential. The surface of the specimen should be adequately cleaned before being inspected.

High-Resolution Optical Performance

Achieve unparalleled inspection accuracy with our devices high clarity optics and up to 20x optical zoom. The integrated LED illumination ensures optimal visibility, even when examining challenging or minute features. This makes it especially effective for detecting fine weld flaws and subtle surface defects, enhancing quality assurance across various industrial applications.

Rugged and Portable Design for Field Use

Built from robust mild steel and rated IP54 for dust and water resistance, the device is engineered for demanding environments. Weighing just 1.5 kg, it is easy to carry and operate in the field. The 12-hour battery life supports lengthy inspection tasks, while the intuitive LCD/LED interface ensures user-friendly operation.

Comprehensive Data Management and Compliance

Record and store all inspection data directly with the devices internal memory. Enjoy seamless data review and retrieval thanks to the digital display and straightforward user interface. Compliant with ISO and ASTM NDT standards, this device guarantees reliable measurements suitable for audits, certifications, and quality documentation.

FAQs of Visual Testing:

Q: How does the integrated LED illumination enhance visual inspections?

A: The integrated LED illumination provides consistent and bright lighting for the inspection area, enabling clearer visualization of microscopic details and detecting flaws that might remain unnoticed under ambient light conditions. This ensures precise analysis and high-quality results, even in poorly lit or challenging environments.Q: What types of applications is this device best suited for?

A: This device is specially engineered for weld inspection, surface flaw detection, and quality control tasks across industries. Its high magnification optics and durable build make it ideal for both routine and critical inspections in fabrication plants, field sites, and maintenance workshops.Q: When should I consider recalibrating the device?

A: The device comes factory pre-calibrated to ensure out-of-the-box accuracy. However, users can perform recalibration if measurement discrepancies are observed or as part of routine maintenance schedules required by specific operation protocols or compliance audits.Q: Where can the device be effectively operated?

A: Thanks to its IP54 protection class and design for portability, the device can be used both indoors and outdoors, including in dusty, damp, or industrial environments. It operates efficiently within a temperature range of 0 to 50C, supporting inspections across varied settings.Q: What is the process for storing inspection records?

A: After each inspection, measurement data and images are automatically saved to the devices internal memory. Users can retrieve and review these records directly via the digital display, enabling streamlined documentation and traceability for audits or further analysis.Q: How does using this device benefit inspection workflows?

A: Employing this device significantly enhances inspection accuracy, speeds up the quality control process, and ensures documentation integrity. Its portability, user-friendly controls, and compliance with international standards make it a valuable tool for service providers seeking efficient and reliable results.

- Main Domestic Market

- North India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Destructive Testing Category

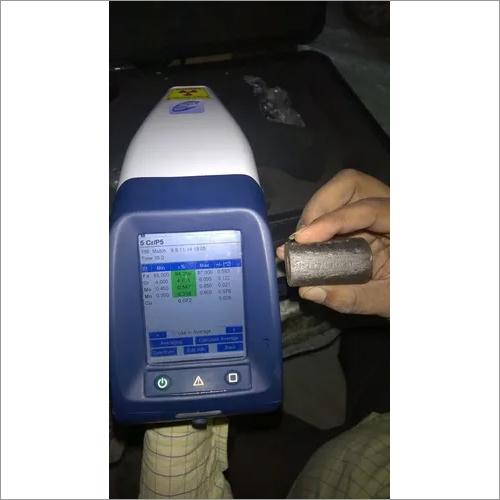

Positive Material Identification

Weight : 2.5 kg (Approx)

Usage & Applications : Positive Material Identification (PMI) in metals and alloys, including quality assurance and sorting

Material : Stainless Steel

Measuring Range : Up to 30 Elements

Driven Type : Battery Operated

Interface : USB / Bluetooth

Ultrasonic Thickness Measurement

Weight : 230 g (including batteries)

Usage & Applications : Measuring thickness of metals, pipes, tanks, and other materials

Material : ABS Plastic

Measuring Range : 1.2 mm 225.0 mm (in steel)

Driven Type : Battery operated

Interface : Userfriendly keypad with LCD display

Ultrasonic Testing

Weight : Approx. 23 kg

Usage & Applications : Flaw Detection, Thickness Measurement, Weld Inspection

Material : Stainless Steel

Measuring Range : 1 mm 300 mm (in steel)

Driven Type : Electric

Interface : Digital, USB/Data Port

Insitu Hardness Testing Services

Weight : 23 Kilograms

Usage & Applications : Hardness Testing of Metal Components On Site

Material : Steel

Measuring Range : 150950 HLD

Driven Type : Electric

Interface : Digital

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese