Positive Material Identification

Positive Material Identification Specification

- Interface

- USB / Bluetooth

- Material

- Stainless Steel

- Driven Type

- Battery Operated

- Usage & Applications

- Positive Material Identification (PMI) in metals and alloys, including quality assurance and sorting

- Temperature

- 0C to +50C

- Frequency

- 50/60 Hz

- Power

- Li-Ion Battery

- Size

- Handheld

- Display

- Digital LCD Touch Screen

- Measuring Range

- Up to 30 Elements

- Voltage

- Rechargeable Battery, 7.4V

- Weight

- 2.5 kg (Approx)

Positive Material Identification Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- North India

- Certifications

- ISO, NABL, ASNT, etc.

About Positive Material Identification

Positive MaterialIdentification (PMI) is one of the more specialised non destructive testingmethods. With positive material identification the alloy composition ofmaterials can be determined. If a material certificate is missing or it is notclear what the composition of a material is, then PMI offers the solution.Because specifications for materials used in industry are increasingly morespecific, the need for PMI testing has been on an increase for the past severalyears. Periodic plant maintenance shutdowns are less frequent and consequentlythe materials used in the plant are in use longer. A wider variety of alloysthat are indistinguishable to the eye are being used in process plants. Whenfacility and inspection staff replace components, they must be able toguarantee that the new part matches required specifications. Recent industrialaccidents have cost the lives of workers and heightened the awareness of theneed for accurate and comprehensive PMI inspections.

The XRF principle (x rayfluorescence) is one of the methods for PMI. Equipment used contains lowradioactive sources (isotopes) or x-ray tubes. The exposed material reflectsthe radiation, generating energy. As every element has it's own atomicstructure, this reflection will generate a different energy level for everyelement. This energy is measured and detected, thus identifying the alloyelements. The other method for PMI is Spark emission spectrography.Spectography is based on optical emission. The equipment consists of a probewhich releases a spark that is used to vapourise the material being analysed.The atoms and ions in this vapour produce a spectrum which can be opticallymeasured and then recalculated to determine the components of the material.Material properties like structure difference and heat treatments have noinfluence on the results of the PMI measurements. However, it is important thatthe surface is identical to rest of the material. Oxides, coatings and dirt onthe material will influence the identification results. Also the surface mustbe smooth. Elements that can be identified using PMI include: Ti, V, Cr, Mn,Co, Fe, Cu, Zn, Ni, Se, Nb, Mo. Interesting to know is that the exposure ofradiation is sufficiently low, so that extra safety measures are not required.When dealing with exploitation licenses and preventive maintenance of technicalinstallations, Non Destructive Testing and Examination (NDT / NDE) areindispensable techniques. NDT / NDE offer also the necessary guarantees whenquality, expense saving, business security and safety is in order, for bothexisting and new installations. NDT / NDE decrease the risk of leakage or otherdefects, which increase the business integrity and safety within theinstallation and can save expenses.

Product details

| Material Type | SS,Copper,Nickle,Steel |

| No Of Unit To Be Tested | 200 |

| Industry Type | Refineries, Production, Chemical Plant |

| Location/City | Pan India |

| Sample Test Location | Customer Place |

| Product Type | Alloy |

| Mode Of Report | Soft Copy |

| Usage/Application | Material Sorting |

| Test Location | Customer Place |

| Application Type | Material Sorting |

| Testing Type | Non Destructive Testing Services |

| Service Duration | As desired by Customer |

| Destination | All India |

| Type Of Service Provider | Inspection and Testing Engineers |

| Need Test Result | <2 Hours |

| Calibration Check Required | Yes |

| Need Standard Certification | Yes |

High-Speed, Accurate Material Verification

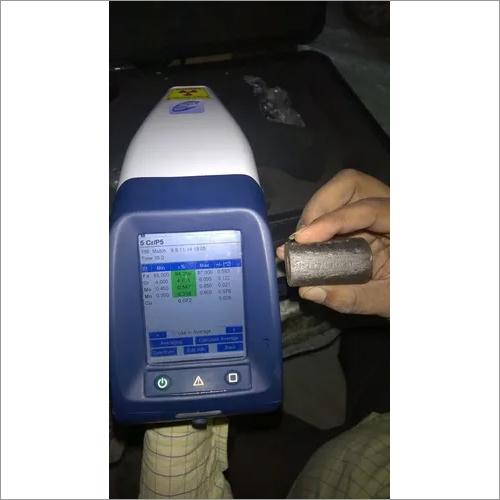

Experience rapid response times between 1 and 3 seconds for precise Positive Material Identification (PMI) using advanced X-ray Fluorescence (XRF) analysis. Ideal for metals and alloys, this handheld device combines efficiency and accuracy, making it essential for quality assurance and sorting in industrial environments.

User-Friendly and Reliable Design

With its stainless steel housing and approximately 2.5 kg weight, this PMI tester is built for durability and portability. The digital LCD touchscreen offers clear, high-resolution output, while automatic factory calibration and straightforward interface ensure ease of use, even in challenging conditions found across India.

Extended Operation and Convenient Data Handling

Powered by a rechargeable 7.4V Li-Ion battery for up to 8 hours, this device meets the demands of busy fieldwork. Internal memory and SD card support facilitate extensive data storage. USB and Bluetooth connectivity streamline data transfer to your systems for further analysis or reporting.

FAQs of Positive Material Identification:

Q: How does this PMI device ensure accurate material identification?

A: The device utilizes X-ray Fluorescence (XRF) technology, combined with automatic factory calibration, to precisely identify up to 30 elements within metals and alloys. High-resolution digital display and rapid response times of 13 seconds contribute to consistent and reliable analysis.Q: What is the process for using the handheld PMI analyzer?

A: Simply place the analyzers test window on the material surface, start the measurement through the touchscreen, and receive elemental identification almost instantly. All results are displayed on the digital LCD and stored internally or on an SD card for future reference.Q: When should a Positive Material Identification test be conducted?

A: PMI tests are recommended during quality assurance procedures, materials sorting, or whenever verification of metal alloy composition is needed, especially before critical manufacturing, repairs, or equipment fabrication.Q: Where can this XRF-based PMI device be effectively used?

A: The device is designed for heavy-duty field and industrial use across India. Its humidity tolerance (up to 90% non-condensing) and wide operating temperature range (0C to +50C) allow for reliable performance both indoors and outdoors.Q: What are the storage and data transfer options available?

A: Test data can be saved either in the devices internal memory or on an SD card for expanded storage. For easy reporting and analysis, data can be quickly exported via USB or Bluetooth interfaces to computers or compatible devices.Q: How does the long battery backup benefit users?

A: The 7.4V rechargeable Li-Ion battery delivers up to 8 hours of uninterrupted operation, supporting extended onsite analyses without frequent recharging, vital for remote or large-scale work environments.Q: What are the primary benefits of using this handheld PMI analyzer?

A: This analyzer delivers rapid, accurate, and non-destructive results, enhances workflow efficiency, and reduces errors. Its robust design, user-friendly interface, and flexible data management make it an indispensable tool for metal verification in various industries.

- Main Domestic Market

- North India

- Main Export Market(s)

- Middle East, Africa, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Destructive Testing Category

Ultrasonic Thickness Measurement

Interface : Userfriendly keypad with LCD display

Measuring Range : 1.2 mm 225.0 mm (in steel)

Size : 150 mm x 74 mm x 32 mm

Usage & Applications : Measuring thickness of metals, pipes, tanks, and other materials

Weight : 230 g (including batteries)

Temperature : 10C to 60C (operating)

Insitu Hardness Testing Services

Interface : Digital

Measuring Range : 150950 HLD

Size : Portable

Usage & Applications : Hardness Testing of Metal Components On Site

Weight : 23 Kilograms

Temperature : 050 Degree Celsius

Visual Testing

Interface : Digital display

Measuring Range : Up to 100 mm (depth)

Size : Portable / Handheld

Usage & Applications : Weld inspection, surface flaw detection, quality control

Weight : 1.5 kg

Temperature : 0 to 50C

Liquid Penetrant Testing

Interface : Manual application (spray, brush, or immersion)

Measuring Range : Surface defect detection (visibility depends on flaw size and test surface)

Size : Standard container sizes: 1 Litre, 5 Litres, 20 Litres (others available on request)

Usage & Applications : Detection of surfacebreaking defects on ferrous and nonferrous metals, ceramics, and nonporous materials. Widely used in metal fabrication, aerospace, automotive, and welding inspection.

Weight : Varies with container size

Temperature : Optimal working temperature: 10C to 50C

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese