Online Condenser Helium Leak Testing

Online Condenser Helium Leak Testing Specification

- Voltage

- 220-240V AC

- Temperature

- Operating range: 10C to 50C

- Usage & Applications

- For detecting and measuring leaks in online condenser systems using helium as tracer gas

- Display

- Digital LCD/LED Display

- Power

- 1.52 kW

- Size

- Custom / As per requirement

- Weight

- Approx. 150-250 kg (varies as per configuration)

- Measuring Range

- 1 x 10 mbarl/sec to 1 x 10 mbarl/sec

- Frequency

- 50/60 Hz

- Material

- Stainless Steel

- Driven Type

- Electric

- Interface

- Digital Interface with alarm system

Online Condenser Helium Leak Testing Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- North India

- Certifications

- ASNT, ISO, NABL, etc.

About Online Condenser Helium Leak Testing

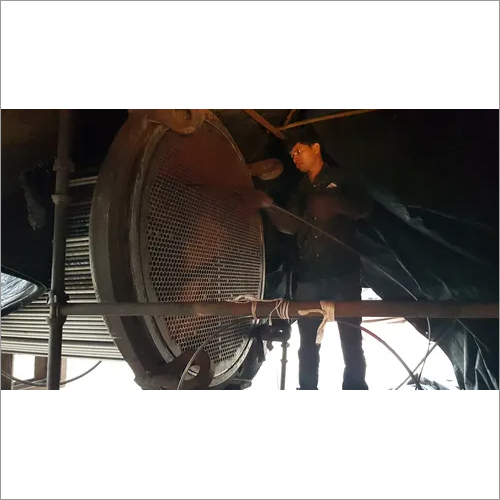

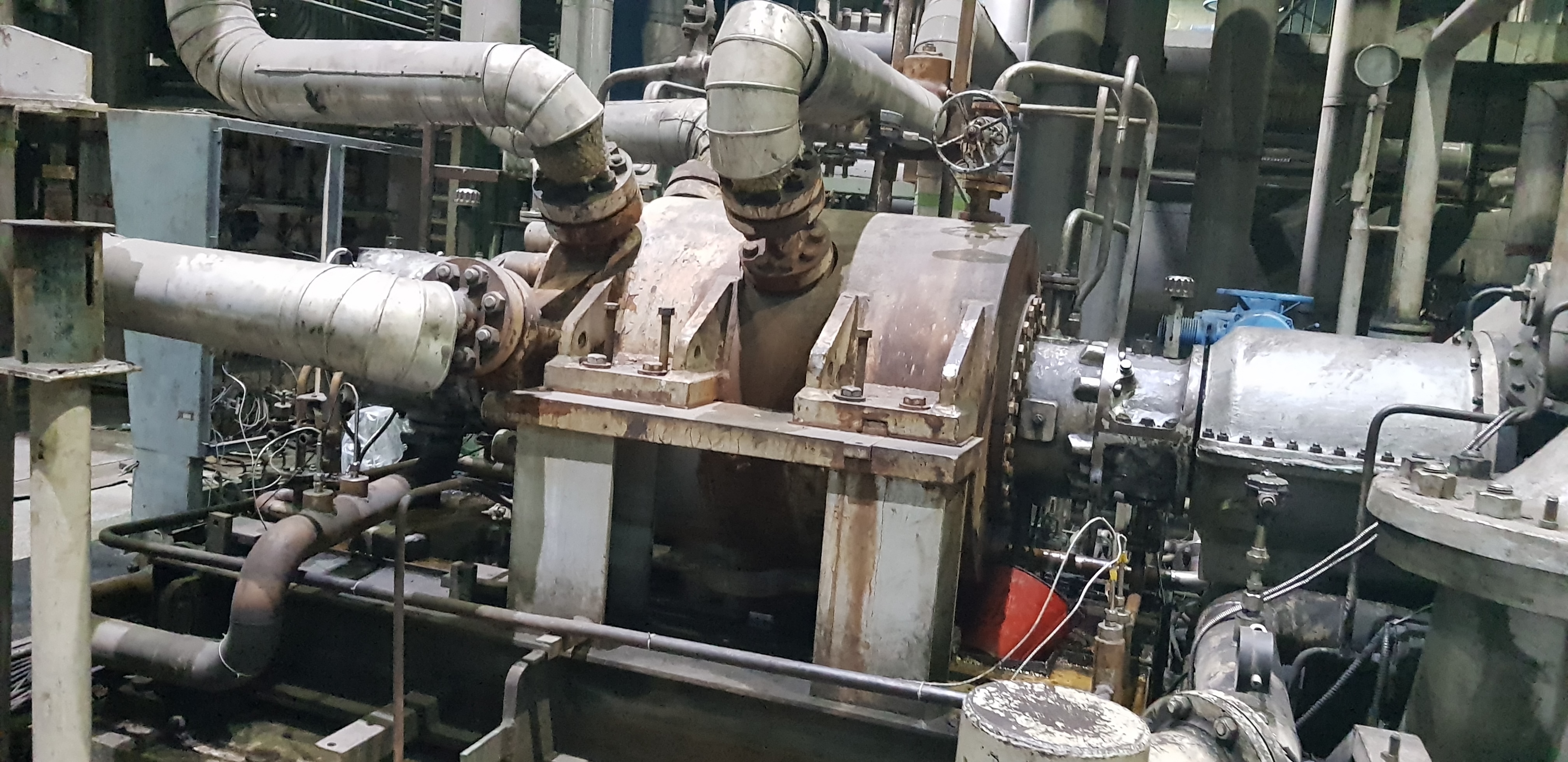

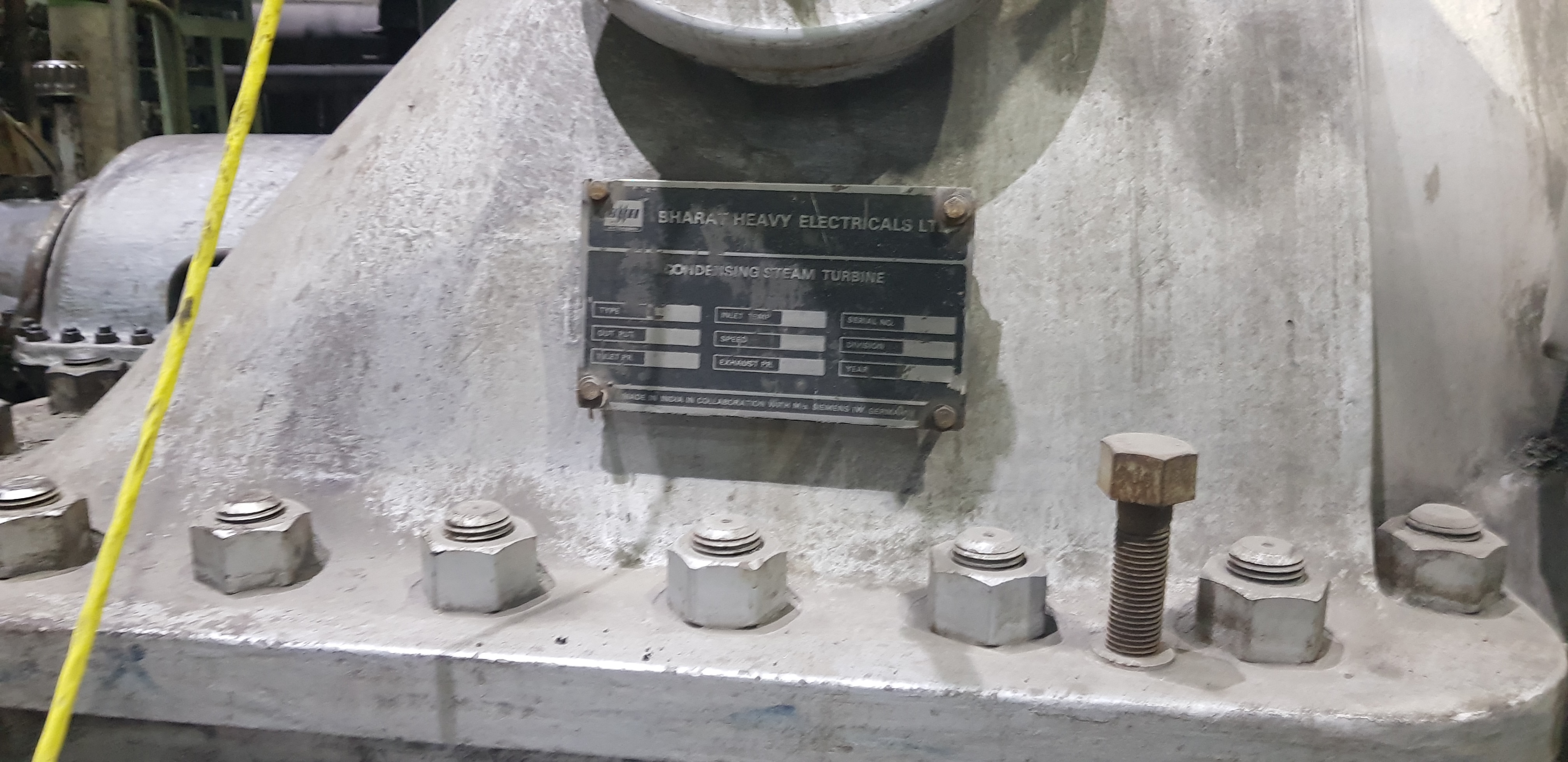

There are various challengesfaced by the teams looking after the operation of turbines in any power plant.The most common of such challenge is maintaining proper vacuum in the condenserto ensure proper output. If the vacuum gets reduced below certain point due toany leakage, then the turbine cannot generate sufficient or desired electricityit is designed for. This leads to significant loss of revenue. Over a period oftime, ITE Has developed capabilities in providing solutions to the customers inidentification of Air Ingress Points throughout the negative pressure part ofthe condenser unit just below the turbine without the need of switching of theturbine. The system could be tested in the running condition and areas could beidentified for repair and maintenance at the next opportunity. Helium Gas isused as a tracer gas which is sprayed over the areas suspected for leakages. Ifthere is any leakage, the helium gas will be sucked in the system and detectedat the exit point where Sniffer probe of the Helium Leak Detector is held.

ITE has been providing theseOnline Condenser Leak Testing services also sometime referred as NegativePressure Part Online Leak Testing to organizations like NTPC, Gujarat StateElectricity Corporation Limited, MadhyaPradesh Power Generation Corporation Limited, etc. to name a few.

Areas Served :- Delhi, Uttar Pradesh, Haryana, Punjab, Maharashtra, Bihar, Rajasthan, Himachal Pradesh, Uttarakhand, Madhya Pradesh, Jammu & Kashmir, Gujarat, Sikkim, Greater Noida, Ghaziabad, Noida, Nepal, Entire North India and South India, United Arab Emirates, Dubai, Qatar, Saudi Arabia, Africa, Egypt, Bahrain, Oman, etc.

Product details

| Type Of Testing Machines | Leak Detector |

| Display Type | Digital |

| Material | Vessels, Valves, Pipelines, Heat Exchangers, Condensers |

| Machine Type | Mass Spectrometer based Leak Detector |

| Testing Type | Helium Leak Testing Services (HLT) |

| Service Type | Non Destructive Testing |

| Test Location | Pan India |

| Usage/Application | Mechanical, Electrical, Automotive, Aeronautical, Fabrcation, etc. |

| Certification Scheme | ASNT, ISO |

| Testing Methodology | Helium Leak Testing |

| Sampling Procedure | As required |

| Application Type | Petrochemical |

| Product Type | Valves, Condenser, Pipelines, Heat Exchangers, Tanks, Vessels |

| Methodology | Sniffer Method |

| Value Data Report On | Leakage |

| Sector Type | Power Generation |

| Vacuum Type | Pressure Vacuum |

| Standard Authorities | ASME, ISO |

| Duration Of Tests | 1 Day |

| Testing Technique | Sniffer,Tracer Probe,Hood Method |

| Weld Verification Required | No |

Precision Detection for Condenser Leaks

Employing helium as the tracer medium, this system offers highly sensitive leak detection capabilities, identifying even minute leaks in condenser systems. With a measuring range from 1 x 10 to 1 x 10 mbarl/sec, you can trust in its accuracy for critical applications.

Effortless Operation & Mobility

The PLC-based automatic control and digital LCD/LED display make the tester user-friendly, while its skid or trolley mounting provides excellent mobility. Maintenance teams can easily move and operate the equipment within different locations at your facility.

Comprehensive Data Management & Safety

Audit and ensure traceability with USB or RS232 data outputs. The built-in audio-visual alarm system provides real-time feedback on test results, enhancing operational safety. The IP54 enclosure delivers reliable protection in various industrial environments.

FAQs of Online Condenser Helium Leak Testing:

Q: How does the helium mass spectrometer leak test work for condensers?

A: The helium mass spectrometer leak test uses helium gas as a tracer, introducing it into the condenser system. The spectrometer detects any escaping helium with very high sensitivity, allowing for rapid and accurate identification of system leaks.Q: What are the key benefits of using this online condenser helium leak tester?

A: Benefits include quick test cycles (typically under 2 minutes per unit), high detection sensitivity ( 1 x 10 mbarl/sec), automated PLC sequencing, and portable skid/trolley mounting for flexible use. Audio-visual alarms and robust data outputs enable safe and traceable operations.Q: When and where should this leak testing equipment be used?

A: This tester is ideal for use during manufacturing, maintenance, or quality assurance of condenser systems within power plants, HVAC units, and industrial settings. It can be used wherever reliable and fast leak detection is critical.Q: What is the process for conducting a leak test with this instrument?

A: Simply connect the condenser to the system, initiate the vacuum pump with either oil-sealed rotary or dry options, introduce helium gas, and allow the PLC-controlled sequence to operate. The system will automatically detect leaks and notify via an audio-visual alarm.Q: How is data recorded and retrieved from the leak tester?

A: The system is equipped with USB and RS232 interfaces, allowing for easy export and traceability of test results. Digital LCD/LED displays provide real-time readings during the process.Q: What kind of installation and support services are provided with the equipment?

A: On-site installation and comprehensive training are provided to ensure your team can operate the system efficiently and maintain reliable performance. Ongoing support is available throughout India.

- Main Domestic Market

- North India

- Main Export Market(s)

- Middle East, Africa, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Helium Leak Testing

Weight : Varies as per model and application

Temperature : Operating range: 0C to 50C

Voltage : 110240 V AC

Usage & Applications : Vacuum Systems, Automotive, Aerospace, Pharmaceutical, Power Plant Equipment, Sealed Components Testing

Display : Digital LCD/LED

Size : Customizable or standard depending on application

Borescopic Inspection Services

Weight : Lightweight, Approx. 0.5 2.5 kg (depending on configuration)

Temperature : Operating range from 10C to 60C (probe dependent)

Voltage : AC 110240V (adapter for equipment), or DC 12V (battery)

Usage & Applications : Internal visual inspection of inaccessible areas in pipelines, turbines, engines, vessels, welds, and structural cavities across industry sectors such as Oil & Gas, Aviation, Power, and Manufacturing.

Display : Highresolution LCD, LED or TFT digital display

Size : Customizable Probe Lengths (commonly 1m to 10m)

Eddy Current Testing of Heat Exchanger Tubes (ECT)

Weight : Portable setup, approximately 58 kg

Temperature : Operating range: 0C to 50C

Voltage : 110V/220V AC, 5060 Hz

Usage & Applications : Detection of defects, cracks, corrosion, and wall thinning in heat exchanger and condenser tubes in various industries such as power plants, refineries, petrochemical, and HVAC plants

Display : LCD/LED digital display

Size : Any tube OD, typically 6mm to 50mm

Remote Field Eddy Current Testing of Heat Exchanger Tubes

Weight : Portable probe unit approx. 1.5 kg

Temperature : Operating range 0C to 50C

Voltage : Input 110240V AC, 50/60Hz

Usage & Applications : Detection of corrosion, wall loss, pitting in heat exchanger tubes

Display : Color LCD digital display, realtime flaw imaging

Size : Suitable for tube inner diameters 12mm to 50mm

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese