Borescopic Inspection Services

Borescopic Inspection Services Specification

- Voltage

- AC 110-240V (adapter for equipment), or DC 12V (battery)

- Temperature

- Operating range from -10C to 60C (probe dependent)

- Material

- Flexible Fiber Optic Cable

- Weight

- Lightweight, Approx. 0.5 - 2.5 kg (depending on configuration)

- Display

- High-resolution LCD, LED or TFT digital display

- Size

- Customizable Probe Lengths (commonly 1m to 10m)

- Measuring Range

- Visual inspection only; Not a dimensional measuring tool

- Usage & Applications

- Internal visual inspection of inaccessible areas in pipelines, turbines, engines, vessels, welds, and structural cavities across industry sectors such as Oil & Gas, Aviation, Power, and Manufacturing.

- Interface

- Compatible with digital displays, USB, SD card, and video output interfaces.

- Driven Type

- Manual articulated or motorized control depending on probe type

- Frequency

- 50 Hz/60 Hz power compatible

- Power

- Rechargeable battery or mains powered supply

- Image/Video Capture

- Still image and video recording supported

- Inspection Depth

- Up to 10 meters (probe specific)

- Waterproof Level

- IP67 or higher (probe only)

- Illumination

- High-intensity adjustable LED lighting

- Service Mode

- Onsite or Offsite inspection service

- Resolution

- 640x480 up to 1920x1080 (depending on system)

- Camera Diameter

- 3.9 mm to 8 mm (various options for different access)

- Data Output

- Digital video, photo, and inspection report documentation

- Articulation

- 2-way or 4-way tip articulation for enhanced maneuverability

Borescopic Inspection Services Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Available

- Yes

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- North India

- Certifications

- ASNT, ISO, NABL, etc.

About Borescopic Inspection Services

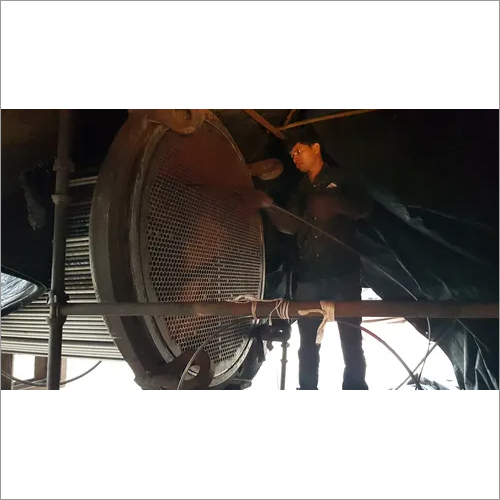

A borescope is a device which is used toinspect the items with small bores or items with limited entrance space whereinspection other wise would not be possible because of lack of approach. It isoften referred to as videoscope. Inspections using such a device is referred toas Borescopy or Videoscopy or Borescopic Inspection or Videoscopic Inspection.

Items like tubes, boiler headers, pipes,boiler tubes, turbine connection, aircraft engines, turbines, automobile components, where inspection using naked eye or with physically being there isnot possible, we can use a videoscope of desired length an diameter and canperform the visual inspection.

ITE is providing borescopic inspectionservices for more than a decade using its best in class equipment. Infact ITEis the one of the only Inspection Company in India which has an IndustrialVideoscope of 18 meters length from Olympus.

Borescopy or videoscopy or borescopic inspection is used in areas which are inaccessible in normal conditions. The inaccessibility of those areas may be because of their size or risk associated with reaching them.

Versatile Access and Imaging

Our borescopes are equipped with highly flexible, fiber optic cables and tips ranging from 3.9 mm to 8 mm in diameter. With custom lengths up to 10 meters, we ensure access to narrow or deep spaces within pipelines, turbines, and engines, facilitating detailed inspections of structures that are usually hidden from view.

Advanced Visualization and Reporting

Each inspection utilizes high-resolution cameras (up to 1920x1080) and adjustable LED illumination for optimal clarity. We capture both images and videos, providing comprehensive documentation and digital reports. Our system interfaces with multiple output options including USB, SD card, and direct displays for complete convenience.

Flexible Service and User Adaptability

Inspections can be performed onsite or offsite, depending on your requirements. Our lightweight and portable equipment, coupled with manual or motorized articulation, adapts seamlessly to a variety of usage scenarios, ensuring both precision and ease of operation across industrial sectors.

FAQs of Borescopic Inspection Services:

Q: How does a borescopic inspection service work?

A: A trained technician inserts a borescope with a small camera (3.98 mm diameter) and adjustable articulation into inaccessible internal areas. Real-time images and videos are visualized, recorded, and later provided as part of a detailed inspection report.Q: What types of industries and components can benefit from these inspection services?

A: Our borescopic inspection services are ideal for industries such as oil & gas, aviation, power generation, and manufacturing. Commonly inspected components include pipelines, turbines, engines, welds, and structural cavities that require non-destructive internal inspections.Q: When should I schedule a borescopic inspection?

A: Schedule a borescopic inspection during preventive maintenance, before or after repair work, when diagnosing faults, or as part of quality control and regulatory compliance routines.Q: Where are borescopic inspections typically performed?

A: Inspections can be carried out either onsite at your facility or offsite at our service location in India, depending on the accessibility of the equipment and operational preferences.Q: What is the process for obtaining a borescopic inspection report?

A: Following the inspection, our team captures digital images and videos, analyzes the findings, and delivers a comprehensive report that includes visual documentation and relevant observations regarding asset condition.Q: What are the main benefits of using professional borescopic inspection services?

A: Professional borescopic inspections offer non-invasive, high-resolution visuals of critical internal parts, facilitate early detection of potential issues, minimize downtime, and help ensure operational safety and compliance without requiring full disassembly.

- Main Domestic Market

- North India

- Main Export Market(s)

- Middle East, Africa, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Helium Leak Testing

Measuring Range : 10 to 1 mbar l/s

Usage & Applications : Vacuum Systems, Automotive, Aerospace, Pharmaceutical, Power Plant Equipment, Sealed Components Testing

Frequency : 50/60 Hz

Interface : Digital and analog output interfaces, RS232/RS485, USB

Temperature : Operating range: 0C to 50C

Driven Type : Electric

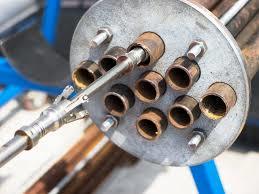

Remote Field Eddy Current Testing of Heat Exchanger Tubes

Measuring Range : Tube lengths up to 30 meters

Usage & Applications : Detection of corrosion, wall loss, pitting in heat exchanger tubes

Frequency : 10 Hz to 50 kHz (test selectable)

Interface : USB, Ethernet, wireless data transmission

Temperature : Operating range 0C to 50C

Driven Type : Electric, automated probe drive

Internal Rotatory Inspection System

Measuring Range : 40 mm to 400 mm (internal diameters)

Usage & Applications : Inspection of internal surfaces of pipes and tubes

Frequency : 50 Hz

Interface : Digital & Analog options

Temperature : Operating range 0C to 60C

Driven Type : Motorized

Oxide Scale Measurement of for boiler tubes

Measuring Range : 05 mm (oxide scale thickness)

Usage & Applications : Onsite measurement of oxide scales on boiler tubes in thermal power plants, refineries, and industrial boilers

Frequency : 50/60 Hz (for AC powered models)

Interface : Digital with USB or serial output (RS232/RS485 options)

Temperature : Measuring capacity up to 600C (device operating range 050C)

Driven Type : Microprocessor based electronic

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese