Ultrasonic Thickness Measurement

Ultrasonic Thickness Measurement Specification

- Driven Type

- Battery operated

- Power

- 3V (2 x AA batteries)

- Weight

- 230 g (including batteries)

- Voltage

- 2 x 1.5V AA batteries

- Display

- 4-digit LCD

- Temperature

- -10C to 60C (operating)

- Usage & Applications

- Measuring thickness of metals, pipes, tanks, and other materials

- Measuring Range

- 1.2 mm - 225.0 mm (in steel)

- Frequency

- 5 MHz

- Material

- ABS Plastic

- Interface

- User-friendly keypad with LCD display

- Size

- 150 mm x 74 mm x 32 mm

- Storage Humidity

- <80% RH

- Sound Velocity Range

- 1000 m/s - 9999 m/s

- Data Hold Function

- Available

- Accuracy

- ±(1%H+0.1) mm

- Case Material

- Impact-resistant plastic

- Backlight

- Available

- Auto Power Off

- Yes, after 5 minutes of inactivity

- Resolution

- 0.1 mm

- Low Battery Indicator

- Yes

- Probe Type

- Single crystal 8mm diameter

Ultrasonic Thickness Measurement Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Africa, Middle East, Asia

- Main Domestic Market

- North India

About Ultrasonic Thickness Measurement

Ultrasonic Thickness Measurement is used to check thickness in pipes, tubes and other metallic items where reduction in thickness can lead to unwanted stopages.

For eg. In power plants, boiler tubes are regularly checked for reduction in thickness. If any tube is faulty i.e. has less thickness than what is desired then it may lead to rupture in tube and the complete system will become inefficient. Hence, it is mandatory to keep on checking the tubes for thickness to avoid unwanted and unnecessary breakdowns.

Cutting-Edge Precision and Versatility

With a measurement range from 1.2 mm up to 225.0 mm in steel and a resolution of 0.1 mm, this ultrasonic thickness gauge provides exceptional accuracy across a spectrum of metallic and non-metallic materials. Whether in fabrication shops or onsite inspections, users can depend on its (1%H+0.1) mm accuracy for critical measurements.

Designed for Rugged Environments

Constructed with impact-resistant ABS plastic, this device is built to withstand demanding industrial conditions. Its lightweight design and compact size (150 x 74 x 32 mm) make it effortless to transport and use, even in challenging settings. The auto power-off function and low battery indicator help conserve energy for prolonged use.

Intuitive Operation and Reliable Results

A user-friendly keypad, a clear four-digit LCD display with backlight, and convenient data hold functionality simplify operation for professionals at every level. The device runs efficiently on two AA batteries and supports operation in temperatures ranging from -10C to 60C, making it adaptable for diverse field applications.

FAQs of Ultrasonic Thickness Measurement:

Q: How does the ultrasonic thickness gauge measure material thickness?

A: The device uses ultrasonic pulses transmitted through a single crystal probe to measure the time it takes for sound waves to travel through the material. This time is converted to thickness using the materials sound velocity, which can be set between 1000 m/s and 9999 m/s.Q: What materials can be measured using this thickness gauge?

A: It is suitable for a wide variety of materials including metals, pipes, tanks, and selected non-metallic substances, provided their sound velocity falls within the specified range. Its accuracy and wide measuring range make it ideal for industrial quality control and maintenance tasks.Q: When should I use the data hold and backlight features?

A: Activate the data hold function to lock a measurement when working in difficult-to-reach places or under time constraints. The backlight aids in low-light environments, ensuring that results remain visible and clear regardless of lighting conditions.Q: Where is this ultrasonic thickness measurement device typically used?

A: The device finds applications in fabrication plants, construction sites, and maintenance workshops across India. It is particularly useful for thickness evaluation of steel structures, pipelines, storage tanks, and quality assurance in manufacturing processes.Q: What is the operating process for this thickness gauge?

A: To operate, switch on the device using the keypad, place the 8mm single crystal probe onto the cleaned material surface, and input the correct sound velocity. The display will then show the accurate thickness reading in real time.Q: What are the main benefits of using this ultrasonic thickness gauge?

A: Users benefit from its accuracy, robust build, energy-efficient operation, and ease of use. Features such as auto-off, data hold, low battery indicator, and a backlit LCD screen make it reliable for both field and laboratory work.

- Main Domestic Market

- North India

- Main Export Market(s)

- Africa, Middle East, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Destructive Testing Category

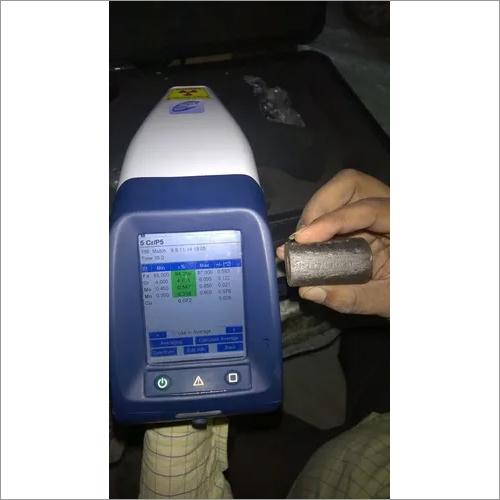

Positive Material Identification

Temperature : 0C to +50C

Usage & Applications : Positive Material Identification (PMI) in metals and alloys, including quality assurance and sorting

Measuring Range : Up to 30 Elements

Size : Handheld

Interface : USB / Bluetooth

Material : Stainless Steel

Ultrasonic Testing

Temperature : Operating: 0C to 50C

Usage & Applications : Flaw Detection, Thickness Measurement, Weld Inspection

Measuring Range : 1 mm 300 mm (in steel)

Size : Portable, Handheld Unit

Interface : Digital, USB/Data Port

Material : Stainless Steel

Insitu Hardness Testing Services

Temperature : 050 Degree Celsius

Usage & Applications : Hardness Testing of Metal Components On Site

Measuring Range : 150950 HLD

Size : Portable

Interface : Digital

Material : Steel

Visual Testing

Temperature : 0 to 50C

Usage & Applications : Weld inspection, surface flaw detection, quality control

Measuring Range : Up to 100 mm (depth)

Size : Portable / Handheld

Interface : Digital display

Material : mild steel

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese