ASNT Level II in PAUT

ASNT Level II in PAUT Specification

- certificate type

- ASNT Level II

- Course Duration

- 4 to 5 days

- Batch Size

- Limited for individual attention

- Standard

- ASNT SNT-TC-1A

- Support

- Post-course technical support for industrial applications

- Equipment Used

- Industrial PAUT machines

- Inspection Application

- Detection of weld flaws, corrosion mapping, thickness measurement

- Assessment Method

- Written and Practical Examination

- Training Mode

- Classroom and Hands-on practical

- Certification Level

- Level II

- Location

- Available PAN India at affiliated centers

- Language of Instruction

- English

- Eligibility

- Level I in PAUT or relevant NDT experience

- Study Material

- Comprehensive training manuals provided

- Validity

- Certificate validity as per employers written practice

- Technique

- Phased Array Ultrasonic Testing (PAUT)

- Instructor Qualification

- Certified and experienced ASNT Level III trainers

- Course Name

- ASNT Level II in PAUT

ASNT Level II in PAUT Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID)

- Supply Ability

- 20 Per Week

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Level II classes are taken by ASNT NDT Level III certified Engineer.

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- North India

- Certifications

- NDT Lev - II in PAUT as per ASNT's written practice SNT-TC-1A

About ASNT Level II in PAUT

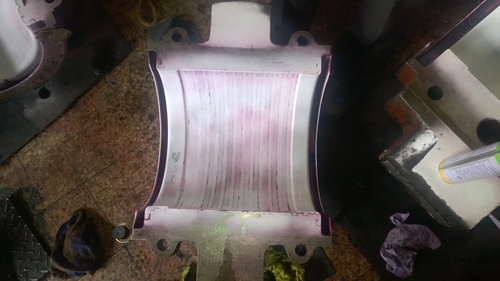

The Phased Array Technique is a process wherein UT data are generated by controlled incremental variation of the ultrasonic beam angle in the azimuthal or lateral direction while scanning the object under examination. This process offers an advantage over processes using conventional search units with fixed beam angles because it acquires considerably more information about the reflecting object by using more aspect angles in direct impingement. Each phased array search unit consists of a series of individually wired transducer elements on a wedge that a reactivated separately using a pre selectable time delay pattern. With a linear delay time between the transmitter pulses, an inclined sound field is generated. Varying the angle of refraction requires a variation of the linear distribution of the delay time. Depending on the search unit design, it is possible to electronically vary either the angle of incidence or the lateral skew angle. In the receiving mode, acoustic energy is received by the elements and the signals undergo a summation process utilizing the same time delay pattern as was used during transmission.

Flaw sizing is normally performed by measuring the vertical extent (in the case of cracks) or the cross sectional distance (in the case of volumetric/planar flaws) at the 6 dB levels once the flaw has been isolated and the image normalized. Tandem sizing and analysis uses techniques similar to pulse-echo but provides images that are easier to interpret since specular reflection is used for defects oriented perpendicular to the surface. For cracks and planar defects, the result should be verified using crack tip diffraction signals from the upper and lower ends of the flaw, since the phased array approach with tomographic reconstruction is most sensitive to flaw tip indications and is able to give a clear reconstruction image of these refraction phenomena. As with other techniques, the phased array process assumes isotropic and homogeneous material whose acoustic velocity is constant and accurately known.

Sectorial scans (S scans) with phased array provides a fan like series of beam angles from a single emission point that can cover part or all of a weld, depending on search unit size, joint geometry, and section thickness. Such a series of beam angles can demonstrate good detectability of side drilled holes because they are omni directional reflectors. This is not necessarily the case for planar reflectors (e.g., lack of fusion and cracks) when utilizing line scanning techniques where the beam could be misoriented to the point they cannot be detected. This is particularly true for thicker sections when using single line scanning techniques.

ITE has expert manpower with years of expertise in performing PAUT of various components including Welding, Castings, Pipes, Tubes, Plates, etc.

As a recent addition to the portfolio of our services we have started performing Phased Arrau Ultrasonic Testing of Boiler Tubes as well with diameter as low as .75 inch to 4.5 inches. This is done used a specialized attachment called Cobra scanner. Cobra scanners used with Olympus Omnis can MX2 with other necessary accessories to perform reliable scanning of Boiler Tubes welded joints. With Cobra Scanner, we have been able to remove various challenges and limitations faced by customers in the power sector. One of them being reduced dependence of Radiography Testing, since PAUT using cobra scanner give better and faster result that Radiography Testing.

Areas Served :- Delhi, Uttar Pradesh, Haryana, Punjab, Maharashtra, Bihar, Rajasthan, Himachal Pradesh, Uttarakhand, Madhya Pradesh, Jammu & Kashmir, Gujarat, Sikkim, Greater Noida, Ghaziabad, Noida, Nepal, Entire North India and South India, United Arab Emirates, Dubai, Qatar, Saudi Arabia, Africa, Egypt, Bahrain, Oman, etc.

Expert-Led Practical Training

Led by certified ASNT Level III instructors, the course combines in-depth theoretical knowledge with extensive hands-on sessions using industrial PAUT machines. This balanced approach ensures participants develop both the technical understanding and the practical skills needed for effective application in various inspection environments.

Comprehensive Coverage and Support

From weld flaw detection to corrosion mapping and thickness measurement, the curriculum is structured to address diverse industrial inspection challenges. Participants benefit from detailed training manuals and post-training technical support, ensuring ongoing professional growth and competence in PAUT techniques.

Nationwide Accessibility and Individual Attention

The course is offered PAN India at affiliated centers, making it widely accessible. With limited batch sizes, instructors dedicate individual attention to each participant, fostering a supportive and effective learning environment.

FAQs of ASNT Level II in PAUT:

Q: How is the ASNT Level II in PAUT training conducted?

A: The training combines classroom instruction with hands-on practical sessions using industrial PAUT equipment. Delivered in English, it covers both theory and real-world application, allowing participants to gain practical skills under the guidance of certified and experienced ASNT Level III trainers.Q: What are the eligibility requirements for enrolling in this course?

A: Candidates should have completed Level I in PAUT or possess relevant experience in non-destructive testing (NDT). This prerequisite ensures that all participants have a foundational understanding, enabling them to extract maximum value from advanced PAUT techniques taught at Level II.Q: Where can I attend the ASNT Level II in PAUT course?

A: The program is available PAN India at various affiliated centers. A comprehensive list of locations can be provided by the service provider, ensuring you have access to training close to your preferred area.Q: What topics and applications does the course cover?

A: The curriculum covers detection of weld flaws, corrosion mapping, and thickness measurement using the phased array ultrasonic testing (PAUT) technique. It also includes understanding equipment calibration, interpreting results, and industry-specific inspection applications.Q: When will I receive my certificate upon successfully passing the assessments?

A: Certificates are typically issued promptly after successful completion of both written and practical examinations. The certificates validity aligns with your employers written practice, meeting industry-recognized competency standards.Q: How does the course benefit my career as an NDT professional?

A: Gaining ASNT Level II in PAUT certification demonstrates advanced proficiency to employers, expanding your professional opportunities and qualifying you for more specialized roles in industrial inspection, quality assurance, and safety management.

Price 70800 INR/ Number

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 20 Per Week

- Delivery Time

- 10 Days

- Main Domestic Market

- North India

- Main Export Market(s)

- Middle East, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Training and Certifications Category

ASNT Level II in Magnetic Particle Testing

Price 3000 INR / Number

Minimum Order Quantity : 1 Number

ASNT Level II in Liquid Penetrant Testing

Price 3000 INR / Number

Minimum Order Quantity : 1 , , Number

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese