Radiography Testing

Radiography Testing Specification

- Voltage

- 220 Volt (v)

- Driven Type

- Electric

- Display

- Digital Display

- Usage & Applications

- Non Destructive Testing, Inspection of Welds, Casting, Forging, and Structural components

- Size

- Customizable

- Interface

- Digital Interface

- Frequency

- 50 Hertz (HZ)

- Measuring Range

- Varies as per model

- Weight

- 7 Kilograms (kg)

- Temperature

- 0 to 50 Degree Celsius

- Power

- 50 Watt (w)

- Material

- Mild Steel

- Safety Interlocks

- Integrated

- Protection

- Lead Shielded for Radiation Safety

- Type

- Portable Radiography Unit

- Image Resolution

- High Resolution Imaging

- Mobility

- With Caster Wheels

- Compatible Film

- Industrial Radiographic Film

- Control Panel

- Microprocessor based

- Radiation Source

- X-Ray or Gamma Ray

- Scanning Speed

- Standard/High Speed

- Operating Mode

- Manual/Automatic

Radiography Testing Trade Information

- Main Export Market(s)

- Asia

- Main Domestic Market

- North India

About Radiography Testing

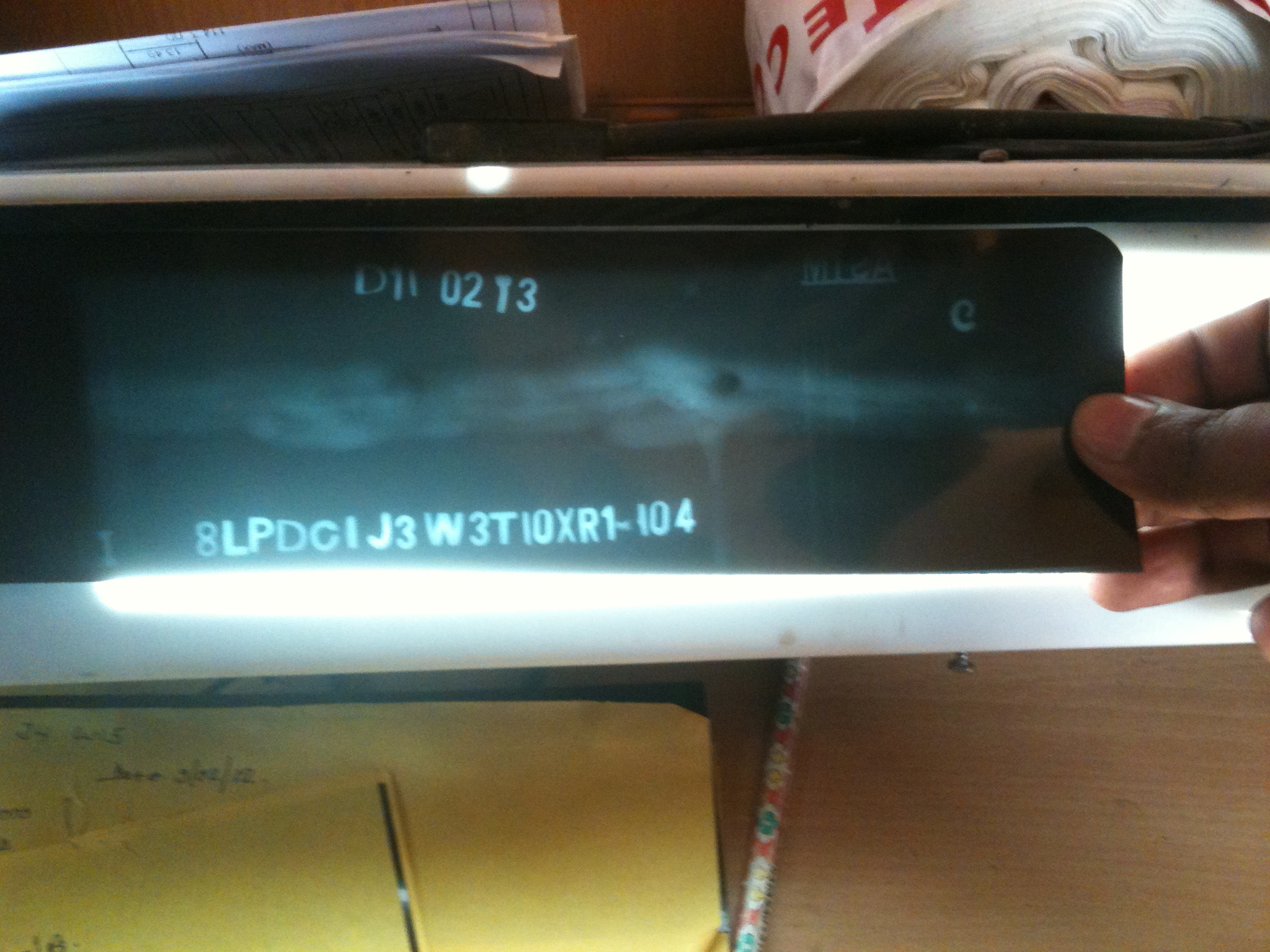

Radiographic Testing (RT), or industrial radiography, is a nondestructive testing (NDT) method of inspecting materials for hidden flaws by using the ability of short wave length electromagnetic radiation (high energy photons) to penetrate various materials.

Either an X-ray machine or a radioactive source (Ir-192 or Co-60) can be used as a source of photons.

Radiography testing (RT) is a non destructive testing (NDT) technique used to evaluate the internal structure and integrity of materials, primarily metals. It involves the use of X rays or gamma rays to create an image of the materials internal structure, which can then be analyzed for defects or irregularities. Radiography testing is commonly used in industries such as manufacturing, construction, and aerospace to ensure the safety and quality of metal components.

The process of radiography testing typically involves the use of a radiography machine, which emits a beam of radiation that penetrates the material being tested. The radiation is absorbed differently by different materials, and this creates a contrast between different parts of the material on the radiographic film or digital detector. This contrast allows the radiographer to identify any defects or inconsistencies within the material.

Radiography testing can detect a wide range of defects, including cracks, voids, inclusions, and porosity. These defects can be caused by a variety of factors, such as manufacturing flaws, material degradation, or physical damage. By identifying these defects, engineers can determine the safety and reliability of a metal component and take appropriate measures to repair or replace it if necessary.

Overall, radiography testing is a highly effective NDT technique that provides engineers with valuable information about the internal structure and quality of metals. It can help to ensure the safety and reliability of metal components in a variety of industries and is an essential tool in the development and production of high quality metal products.

Versatile High-Resolution Radiography

Achieve detailed imaging for critical inspections with this portable radiography unit. Whether examining weld seams, castings, or structural parts, its high-resolution imaging capability delivers reliable results for non-destructive testing in various industries.

Safety and Mobility Combined

This unit prioritizes safety with integrated lead shielding and safety interlocks, reducing radiation risk during operation. Lightweight construction and caster wheels ensure effortless mobility, making it suitable for use across multiple work sites or inspection zones.

Advanced Control and User Convenience

The microprocessor-based control panel, digital interface, and user-friendly display combine to offer easy configuration and real-time monitoring. Both manual and automatic modes enable flexible operation to suit standard or high-speed scanning needs.

FAQs of Radiography Testing:

Q: How does the portable radiography unit enhance non-destructive testing?

A: The unit provides high-resolution X-ray or gamma ray imaging, allowing for thorough inspection of welds, castings, forgings, and structural components without causing damage. Its portability and mobility make it ideal for on-site evaluations in industrial environments.Q: What safety features are integrated into this radiography testing device?

A: Lead shielding and built-in safety interlocks are incorporated to minimize radiation exposure to operators and nearby personnel. These features ensure regulatory compliance and reinforce user safety during all stages of testing.Q: When should I use manual versus automatic operating modes?

A: Manual mode offers precise control for specialized inspections or adjustments, while automatic mode streamlines standard or high-speed scanning tasks. The choice depends on the complexity of the job and the desired inspection speed.Q: Where can this radiography unit be deployed for inspections?

A: Thanks to its compact, 7 kg design and caster wheels, the unit can be easily moved and used in manufacturing plants, construction sites, repair workshops, and other industrial settings requiring portable, high-quality testing.Q: What benefits does the microprocessor-based control panel provide?

A: The advanced control panel enables precise configuration, real-time monitoring, and ease of use. It also supports digital interfacing, enhancing accuracy and documentation during radiographic operations.Q: Which types of radiographic films are compatible with this unit?

A: The unit is designed for use with various industrial radiographic films, ensuring flexibility to adapt to specific imaging and documentation needs across different inspection tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Destructive Testing Category

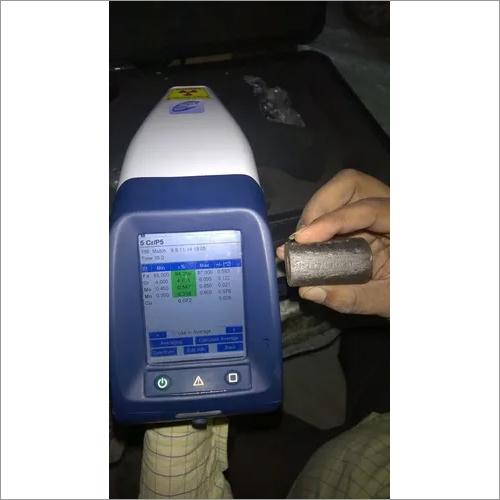

Positive Material Identification

Temperature : 0C to +50C

Material : Stainless Steel

Measuring Range : Up to 30 Elements

Weight : 2.5 kg (Approx)

Usage & Applications : Positive Material Identification (PMI) in metals and alloys, including quality assurance and sorting

Size : Handheld

Ultrasonic Thickness Measurement

Temperature : 10C to 60C (operating)

Material : ABS Plastic

Measuring Range : 1.2 mm 225.0 mm (in steel)

Weight : 230 g (including batteries)

Usage & Applications : Measuring thickness of metals, pipes, tanks, and other materials

Size : 150 mm x 74 mm x 32 mm

Ultrasonic Testing

Temperature : Operating: 0C to 50C

Material : Stainless Steel

Measuring Range : 1 mm 300 mm (in steel)

Weight : Approx. 23 kg

Usage & Applications : Flaw Detection, Thickness Measurement, Weld Inspection

Size : Portable, Handheld Unit

Insitu Hardness Testing Services

Temperature : 050 Degree Celsius

Material : Steel

Measuring Range : 150950 HLD

Weight : 23 Kilograms

Usage & Applications : Hardness Testing of Metal Components On Site

Size : Portable

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese