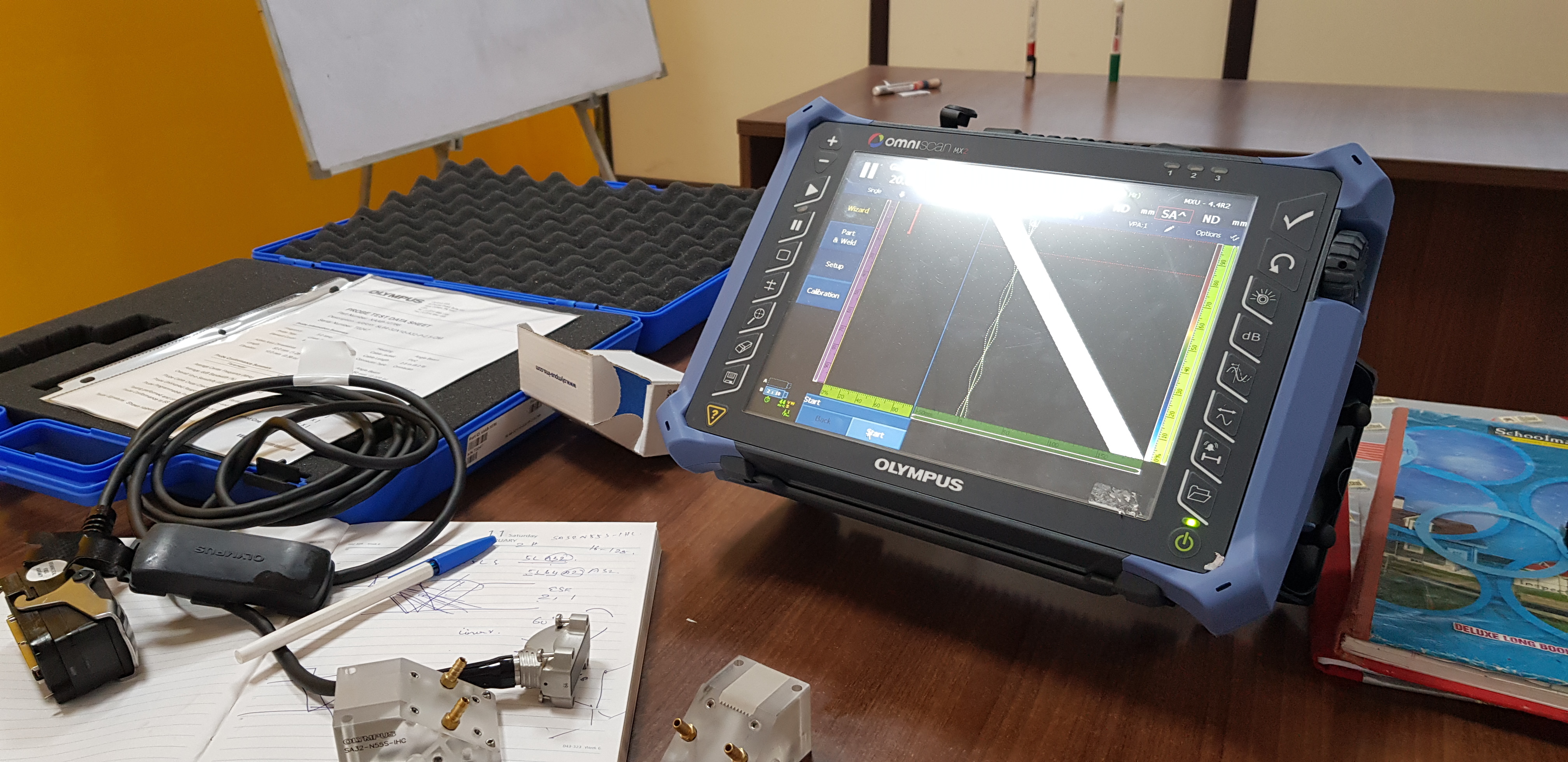

Phased Array Ultrasonic Testing

Phased Array Ultrasonic Testing Specification

- Voltage

- Rechargeable Li-ion battery, 14.8 V

- Temperature

- Operating: 0C to 50C, Storage: -20C to 60C

- Interface

- USB, LAN, HDMI, SD Card Slot

- Weight

- 1.2 kg (with battery installed)

- Material

- ABS industrial grade housing with high-durability polymer and stainless steel connectors

- Usage & Applications

- Inspection of welds, casting, forgings, and composite materials in oil & gas, power generation, aerospace, and shipbuilding industries

- Measuring Range

- 1 mm to 9999 mm (steel)

- Size

- Handheld, 230mm x 150mm x 60mm

- Frequency

- Range 0.5 to 20 MHz selectable

- Power

- 30 W max

- Display

- 8 TFT LCD, 800 x 600 pixel resolution, color touchscreen

- Driven Type

- Battery and mains operated

Phased Array Ultrasonic Testing Trade Information

- Main Export Market(s)

- Africa, Middle East, Asia

- Main Domestic Market

- North India

About Phased Array Ultrasonic Testing

Phased Array Ultrasonic Testing also referred to as PAUT is advanced form of Ultrasonic Testing which is widely used now for inspection of welds and other items . In various cases, RT has also been replaced by PAUT.

Product details

|

Components Of Testing |

Pressure Vessels, Pipeline/Piping, Welded Joints |

|

Type Of Material |

Non-Destructive |

|

Application Type |

Mechanical Engineering |

|

Testing Methodology |

Ultrasonic Testing |

|

Service Type |

New Construction and Inspection |

|

Place Of Testing |

Field |

|

Value Data Report On |

Internal Defects |

|

Certification Scheme |

Any |

|

Industry Body Standards |

ASNT, PCN, AWS, ASME, ISO |

Flexible Probe Compatibility and High Channel Count

The device supports a range of probe configurations with 32, 64, or 128 elements, allowing customization for different materials and inspection depths. Its multi-channel capacity ensures high-resolution scans, making it suitable for complex inspections across diverse industries such as energy, transport, and manufacturing.

Powerful Data Management and Connectivity

Equipped with 16 GB internal memory and expandable SD card support, the tester allows efficient storage of large inspection datasets. Its advanced networking options, including Wi-Fi and Ethernet, enable real-time data transfer for analysis or remote consultation. USB, LAN, and HDMI interfaces provide additional versatility for integration into workflows.

Advanced Flaw Detection and Multilingual Software

With integrated A-Scan, D-Scan, and S-Scan modes, the PAUT device delivers detailed visualization and precise identification of flaws. The included advanced analysis suite supports English, French, German, Spanish, Chinese, and more, making it user-friendly for global teams and service providers.

FAQs of Phased Array Ultrasonic Testing:

Q: How does the PAUT device enhance flaw detection in industrial materials?

A: The device utilizes phased array probes and up to 2048 laws to generate high-resolution ultrasonic images, allowing detailed inspection and reliable detection of defects in welds, castings, forgings, and composites across multiple industries.Q: What is the typical process for using the PAUT device in field inspections?

A: Technicians select the appropriate scanner mode and probe size for the material, calibrate the device (automatically or manually), collect data via scans, and analyze results using the built-in advanced software. Inspection reports are then stored or transmitted as needed.Q: When should the devices internal memory be expanded with an SD card?

A: Expanding the internal memory is recommended when handling frequent inspections, storing large datasets, or archiving previous scan records for long-term projects that require extensive data retention and backup.Q: Where can this ultrasonic tester be used effectively?

A: The device is optimized for use in challenging environments encountered in oil & gas, aerospace, shipbuilding, and power generation. Its IP65 enclosure rating, temperature tolerances, and sturdy build ensure reliable operation both indoors and outdoors across India.Q: What benefits does the advanced flaw detector and analysis suite provide?

A: It offers precise defect characterization, comprehensive scan visualization (A-Scan, D-Scan, S-Scan), multilingual support for global teams, and seamless integration into quality assurance workflows, improving decision-making and inspection reliability.Q: How is real-time data transfer accomplished with the device?

A: Real-time data transfer is facilitated via built-in Wi-Fi and Ethernet connectivity, allowing inspection results to be shared instantly with remote analysts, quality control teams, or company networks for collaborative decision-making.Q: What usage duration can be expected from the devices battery and how is it charged?

A: The rechargeable 14.8V Li-ion battery provides 7-10 hours of continuous operation. The unit can be charged using mains power, ensuring extended usage during prolonged inspections and guaranteeing minimal downtime.

- Main Domestic Market

- North India

- Main Export Market(s)

- Africa, Middle East, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Helium Leak Testing

Measuring Range : 10 to 1 mbar l/s

Size : Customizable or standard depending on application

Voltage : 110240 V AC

Usage & Applications : Vacuum Systems, Automotive, Aerospace, Pharmaceutical, Power Plant Equipment, Sealed Components Testing

Weight : Varies as per model and application

Driven Type : Electric

Eddy Current Testing of Heat Exchanger Tubes (ECT)

Measuring Range : Tube length up to 20 meters

Size : Any tube OD, typically 6mm to 50mm

Voltage : 110V/220V AC, 5060 Hz

Usage & Applications : Detection of defects, cracks, corrosion, and wall thinning in heat exchanger and condenser tubes in various industries such as power plants, refineries, petrochemical, and HVAC plants

Weight : Portable setup, approximately 58 kg

Driven Type : Electrically operated

Time of Flight Diffraction

Measuring Range : 1 mm to 500 mm (depending on probe and material)

Size : Portable, Handheld Unit

Voltage : 100240V AC

Usage & Applications : Detection and sizing of flaws, weld inspection and corrosion mapping in metals

Weight : Approx. 23 kg

Driven Type : Electric

Online Condenser Helium Leak Testing

Measuring Range : 1 x 10 mbarl/sec to 1 x 10 mbarl/sec

Size : Custom / As per requirement

Voltage : 220240V AC

Usage & Applications : For detecting and measuring leaks in online condenser systems using helium as tracer gas

Weight : Approx. 150250 kg (varies as per configuration)

Driven Type : Electric

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese