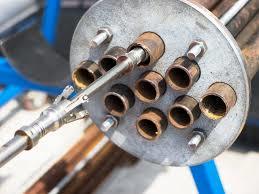

Phased Array Ultrasonic Testing of Boiler Tubes (PAUT)

Phased Array Ultrasonic Testing of Boiler Tubes (PAUT) Specification

- Voltage

- 100 - 240V AC, 50/60Hz

- Weight

- Depends on tube length and material

- Temperature

- -10C to 150C (typical inspection temperature range)

- Size

- 6 mm to 200 mm OD (as per tube specification)

- Measuring Range

- Up to 200 mm wall thickness

- Frequency

- 1 MHz to 10 MHz (probe dependent)

- Usage & Applications

- Detection of corrosion, erosion, pitting, wear, and weld quality in boiler tubes

- Driven Type

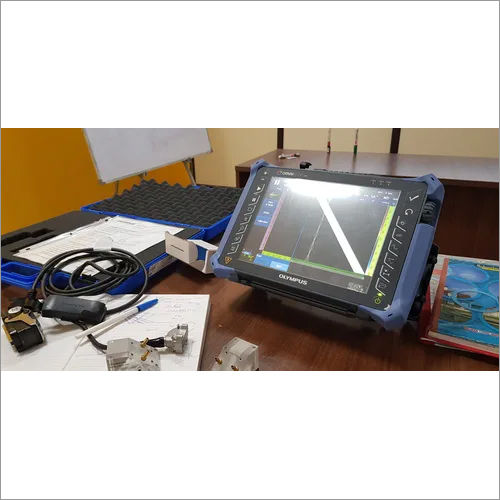

- Electronic, Portable Handheld Unit

- Display

- High-resolution LCD/TFT Touchscreen

- Power

- Battery operated or AC powered

- Material

- Carbon Steel / Alloy Steel / Stainless Steel Boiler Tubes

- Interface

- PAUT system probe with multi-channel electronic connectors

Phased Array Ultrasonic Testing of Boiler Tubes (PAUT) Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Domestic Market

- All India

About Phased Array Ultrasonic Testing of Boiler Tubes (PAUT)

Product details

| Service Type | Condenser leak testing for vacuum drop |

| Test Location | Pan India |

| Usage/Application | Mechanical Engineering |

| Sampling Procedure | Customer Place |

| Display Type | Digital |

| Testing Methodology | Helium Leak Testingg |

| Testing Type | Pressure Testing |

| Application Type | Power Plant |

| Product Type | Condenser |

| Power Source | Electric |

| Value Data Report On | Leakage rate |

| Accuracy | 2 % FS |

| Mode | Online |

| Detection Range | 0-1500 ppm |

Versatile Scanning Capabilities

The PAUT system offers sectorial and linear scanning modes, providing comprehensive coverage of boiler tubes. This versatility enables thorough evaluation across a range of tube diameters and wall thicknesses, making the device adaptable to complex inspection requirements in various industrial applications.

Advanced Data Handling and Automated Reporting

Featuring internal memory and seamless USB/Ethernet download, your inspection data can be securely stored and effortlessly transferred for further analysis. Automated report generation with both C-scan and S-scan outputs streamlines documentation, delivering accurate and standardized results for compliance and record-keeping.

High Accuracy and Sensitivity for Flaw Detection

With defect sizing resolution as fine as 0.01 mm and high sensitivity for micro-defect detection, the system ensures even the smallest flaws are identified. Adhering to rigorous ASME, ASTM, ISO, and EN standards, inspections deliver reliable, repeatable results for critical boiler tube integrity assessment.

FAQs of Phased Array Ultrasonic Testing of Boiler Tubes (PAUT):

Q: How does PAUT detect defects in boiler tubes using sectorial and linear scanning modes?

A: PAUT employs both sectorial and linear scanning techniques to generate ultrasonic waves from multiple angles, allowing detailed visualization of internal tube conditions. Sectorial scanning sweeps the beam across an angular range, while linear scanning traverses along the length, enabling thorough defect detection such as pitting, corrosion, and weld anomalies throughout the tubes structure.Q: What data storage and reporting features are available with this PAUT system?

A: The system is equipped with robust internal memory and supports data export via USB or Ethernet. Automated report generation includes comprehensive C-scan and S-scan outputs, facilitating clear visual representation and documentation of inspection results for compliance and future reference.Q: When and where is PAUT most effectively used for boiler tubes?

A: PAUT is ideal for scheduled maintenance, routine safety audits, or failure investigations in power plants, refineries, and process industries. Its portable design and wide operating temperature range make it suitable for in-situ inspections across varied industrial settings, whether within plant rooms or on-site installations.Q: What is the calibration process for ensuring PAUT accuracy, and which standards are followed?

A: Calibration is performed with standardized reference blocks and is conducted according to ASME or ASTM guidelines. This process ensures the systems defect sizing and detection capabilities are validated and meet international standards for safety and reliability in boiler inspections.Q: What are the benefits of advanced PAUT analysis software included with the package?

A: The included software offers real-time data visualization, defect characterization, and intuitive reporting tools. Users benefit from automated analyses, streamlined workflows, and the ability to interpret both C-scan and S-scan images, enhancing inspection efficiency and decision-making accuracy.Q: Which boiler tube materials and sizes are compatible with this PAUT system?

A: This PAUT solution is compatible with a variety of materials including carbon steel, alloy steel, and stainless steel boiler tubes. It supports diameters from 6 mm up to 200 mm OD, accommodating a broad spectrum of industry-standard tube specifications.Q: How does the system ensure reliable operation in challenging environments?

A: The main unit offers IP65 or IP67 environmental protection, safeguarding it against dust and water. Its durable design, support for water-based or gel couplants, and wide temperature operating range ensure consistent, high-performance inspections even in demanding industrial conditions.

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Advanced Non Destructive Testing Category

Eddy Current Testing of Heat Exchanger Tubes (ECT)

Usage & Applications : Detection of defects, cracks, corrosion, and wall thinning in heat exchanger and condenser tubes in various industries such as power plants, refineries, petrochemical, and HVAC plants

Driven Type : Electrically operated

Frequency : 10 Hz to 10 MHz adjustable

Measuring Range : Tube length up to 20 meters

Power : Max 100 W

Display : LCD/LED digital display

Internal Rotatory Inspection System

Usage & Applications : Inspection of internal surfaces of pipes and tubes

Driven Type : Motorized

Frequency : 50 Hz

Measuring Range : 40 mm to 400 mm (internal diameters)

Power : 100 W

Display : Highresolution LCD

Online Condenser Helium Leak Testing

Usage & Applications : For detecting and measuring leaks in online condenser systems using helium as tracer gas

Driven Type : Electric

Frequency : 50/60 Hz

Measuring Range : 1 x 10 mbarl/sec to 1 x 10 mbarl/sec

Power : 1.52 kW

Display : Digital LCD/LED Display

Borescopic Inspection Services

Usage & Applications : Internal visual inspection of inaccessible areas in pipelines, turbines, engines, vessels, welds, and structural cavities across industry sectors such as Oil & Gas, Aviation, Power, and Manufacturing.

Driven Type : Manual articulated or motorized control depending on probe type

Frequency : 50 Hz/60 Hz power compatible

Measuring Range : Visual inspection only; Not a dimensional measuring tool

Power : Rechargeable battery or mains powered supply

Display : Highresolution LCD, LED or TFT digital display

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese