Rotor Inspection Services

About Rotor Inspection Services

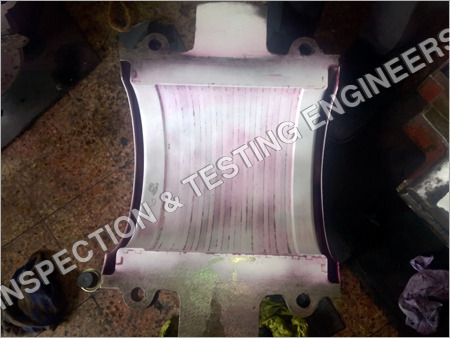

The rotor used in various machines and vehicles are wear items and need their inspection on regular basis. We have made our firm recognition in this field of providing highly efficient solution by offering Rotor Inspection service to the clients. In order to render this service, we are equipped with highly advanced machines and professionals having experience of long years. Providing accurate results, our team of experts keep proper maintenance of machine and work unit on regular time periods. Clients from various heavy duty industries acclaim this service owing to its quality and efficiency. Besides, we provide this Rotor Inspection at budget friendly costs to the clients.

Advanced Non-Destructive Testing Methods

We employ cutting-edge NDT techniques such as ultrasonic, magnetic particle, and dye penetrant testing, ensuring accurate and reliable rotor inspections. These methods enable in-depth structural analysis without causing any damage, making them ideal for ongoing maintenance and integrity assessments in demanding industrial environments.

Certified Technicians, Reliable Results

Our team consists of certified and highly experienced inspectors, capable of handling complex rotor systems in turbines, compressors, and generators. Each inspection is conducted according to established industry standards, delivering trustworthy results and actionable recommendations for improved reliability.

Comprehensive Reporting and 24/7 Support

Clients receive detailed inspection reports, featuring data, images, and professional analysis. Our 24/7 emergency support ensures availability whenever issues arise, minimizing downtime and supporting seamless operation for power plants, manufacturing facilities, and oil & gas sites throughout India.

FAQs of Rotor Inspection Services:

Q: What types of rotors can be inspected by your service?

A: We inspect turbine rotors, generator rotors, and compressor rotors, catering to the needs of industries such as power plants, manufacturing, and oil & gas sectors.Q: How is the rotor inspection process performed?

A: Our inspection process combines non-destructive testing (NDT), meticulous visual examination, and dimensional measurements. Certified technicians utilize advanced tools, inspecting rotors without causing harm, and providing detailed reports post-inspection.Q: When should I schedule a rotor inspection?

A: Rotor inspections can be conducted periodically as part of planned maintenance or as needed in response to specific concerns or operational anomalies. Emergency inspections are available 24/7 across Pan India.Q: Where are these rotor inspection services available?

A: We offer on-site rotor inspection services across all regions of India, ensuring industrial clients nationwide can access expert support when required.Q: What are the benefits of using your rotor inspection services?

A: Our services help detect faults early, prevent unexpected failures, and extend equipment lifespan. By utilizing NDT and experienced personnel, we help maintain operational safety and reduce downtime.Q: Who performs the inspections, and what are their qualifications?

A: All inspections are carried out by certified and experienced technicians trained in advanced NDT methods and rotor analysis. This ensures reliable, industry-compliant results for your critical assets.Q: How can I book the service and what payment modes are accepted?

A: Services can be scheduled according to your requirements, with both offline and online payment options available to suit the operational needs of industrial clients.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Related Inspection & Testing Services Category

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese