Insitu Hardness Testing Services

Insitu Hardness Testing Services Specification

- Usage & Applications

- Hardness Testing of Metal Components On Site

- Measuring Range

- 150-950 HLD

- Interface

- Digital

- Frequency

- 50 Hertz (Hz)

- Power

- Battery Powered

- Temperature

- 0-50 Degree Celsius

- Material

- Steel

- Driven Type

- Electric

- Size

- Portable

- Weight

- 2-3 Kilograms

- Display

- Digital LCD Display

- Voltage

- 110-230 Volt (v)

Insitu Hardness Testing Services Trade Information

- Sample Available

- Yes

- Main Domestic Market

- North India

- Certifications

- ASNT, ISO, NABL, etc.

About Insitu Hardness Testing Services

The term hardness, as it is usedin industry, may be defined as the ability of a material to resist permanentindentation or deformation when in contact with an indenter under load.Generally a hardness test consists of pressing an indenter of known geometryand mechanical properties into the test material. The hardness of the materialis quantified using one of a variety of scales that directly or indirectlyindicate the contact pressure involved in deforming the test surface. Since theindenter is pressed into the material during testing, hardness is also viewedas the ability of a material to resist compressive loads. The indenter may be spherical(Brinell test), pyramidal (Vickers and Knoop tests), or conical (Rockwelltest). In the Brinell, Vickers, and Knoop tests, hardness value is the loadsupported by unit area of the indentation, expressed in kilograms per squaremillimeter (kgf/mm2). In the Rockwell tests, the depth of indentation at aprescribed load is determined and converted to a hardness number (withoutmeasurement units), which is inversely related to the depth.

Hardness testing is perhaps thesimplest and the least expensive method of mechanically characterizing a materialsince it does not require an elaborate specimen preparation, involves ratherinexpensive testing equipment, and is relatively quick. The theoretical andempirical investigations have resulted in fairly accurate quantitativerelationships between hardness and other mechanical properties of materialssuch as ultimate tensile strength, yield strength and strain hardeningcoefficient and fatigue strength and creep. These relationships help measurethese properties with an accuracy sufficient for quality control during the intermediateand final stages of manufacturing. Many times hardness testing is the onlynondestructive test

alternative available to qualifyand release finished components for end application.

Hardness Testing is often usedto verify the effectiveness of the heat treatment applied to actual castings.Its general correlation with the tensile strength of many ferrous alloys allowsa rough prediction of tensile strength to be made.

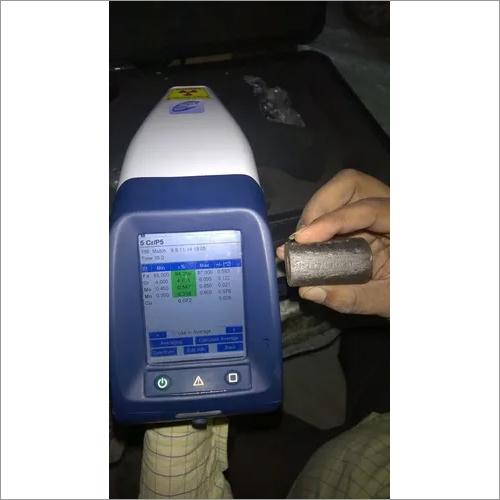

Advanced Onsite Hardness Testing

Our service delivers insitu hardness testing for steel and other metals using portable devices with cutting-edge digital interfaces. Designed for accuracy, each test aligns with the Leeb Rebound principle, allowing immediate results in HLD, HB, HRB, HRC, HV, or HS scales. This technology is engineered to maximize convenience and reliability on manufacturing floors, workshops, and field locations.

Comprehensive Data Handling

Test results are stored internally for up to 500 readings, ensuring extensive record-keeping reliability. Outputs are accessible through USB or RS232 ports, permitting seamless transfer to external systems for analysis and reporting. The service supports both automatic and manual calibration to maintain testing precision.

Optimized for Diverse Conditions

Our instruments function efficiently across varying temperatures (0-50C) and voltages (110-230V, 50 Hz). The portable and lightweight design allows effortless onsite deployment, while the rechargeable Li-ion battery secures extended operational capability. Multiple material modes cater to different alloys and steel grades, ensuring versatile testing.

FAQs of Insitu Hardness Testing Services:

Q: How does Insitu Hardness Testing Services measure material hardness onsite?

A: The service uses portable hardness testers based on the Rebound (Leeb) Hardness Principle, which determines hardness by the rebound velocity of an impact body. The process delivers accurate readings in various scales (HLD, HB, HRB, HRC, HV, HS) directly at your site.Q: What materials can be tested with your insitu hardness testing equipment?

A: Our equipment primarily tests steel and other metal components. It offers multiple material modes to accurately assess a wide range of alloys and grades, ensuring reliable hardness measurements tailored to specific requirements.Q: When is onsite hardness testing most beneficial?

A: Onsite (insitu) hardness testing is particularly advantageous for quality control during fabrication, in-service inspections, maintenance checks, and when it is impractical or costly to transport parts to laboratories. Immediate feedback aids quicker decisions and reduces downtime.Q: Where are your insitu hardness testing services available?

A: Our services are available across India, provided directly at customer locations. From manufacturing plants to field installations, our technicians perform hardness evaluations where components are situated, minimizing transport and handling risks.Q: What is the process for conducting a hardness test with your service?

A: A certified technician calibrates the portable tester (automatically or manually), selects the appropriate material mode, and performs the test by impacting the component. Results are displayed digitally and can be stored or exported for further analysis and reporting.Q: How can test data from onsite hardness measurements be retrieved and utilized?

A: Up to 500 test results are stored in the instrument and can be exported using USB or RS232 ports. This data enables detailed review, documentation, and integration into broader quality or maintenance systems, supporting informed decision-making.Q: What are the main benefits of using portable insitu hardness testing over traditional laboratory methods?

A: Insitu testing offers rapid, location-specific hardness evaluation, eliminates the need for sampling and transport, and enables real-time verification during production, installation, or maintenance, enhancing productivity and reducing operational costs.

- Main Domestic Market

- North India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Destructive Testing Category

Positive Material Identification

Interface : USB / Bluetooth

Material : Stainless Steel

Temperature : 0C to +50C

Usage & Applications : Positive Material Identification (PMI) in metals and alloys, including quality assurance and sorting

Measuring Range : Up to 30 Elements

Driven Type : Battery Operated

Ultrasonic Thickness Measurement

Interface : Userfriendly keypad with LCD display

Material : ABS Plastic

Temperature : 10C to 60C (operating)

Usage & Applications : Measuring thickness of metals, pipes, tanks, and other materials

Measuring Range : 1.2 mm 225.0 mm (in steel)

Driven Type : Battery operated

Ultrasonic Testing

Interface : Digital, USB/Data Port

Material : Stainless Steel

Temperature : Operating: 0C to 50C

Usage & Applications : Flaw Detection, Thickness Measurement, Weld Inspection

Measuring Range : 1 mm 300 mm (in steel)

Driven Type : Electric

Visual Testing

Interface : Digital display

Material : mild steel

Temperature : 0 to 50C

Usage & Applications : Weld inspection, surface flaw detection, quality control

Measuring Range : Up to 100 mm (depth)

Driven Type : Electric

|

INSPECTION & TESTING ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese